Recycling Tin: The Whole Journey

Introduction

Tin, a lustrous member of the IVA family, has left an indelible mark on human history since its first use around 2000 BC. This article delves into the multifaceted world of tin, focusing on its properties, historical significance, and the evolving landscape of the recycled tin industry. As the demand for tin soars across diverse industries, understanding its recycling methods becomes not just a matter of industrial concern but a crucial component of sustainable resource management.

Tin's Enduring Significance and Its Role in Industries

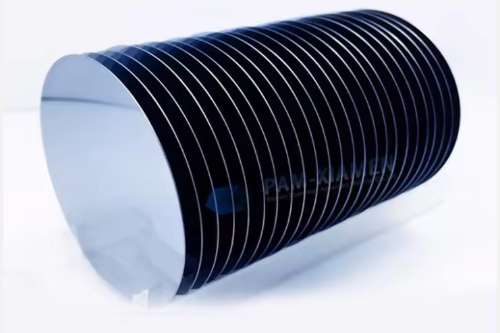

With its atomic number of 50 and a melting point of 231.89°C, tin stands as a silvery-white metal with a low melting point, possessing exceptional properties such as stability, resistance to oxidation, and a shining luster that has made it a cornerstone in various sectors. Beyond its historical applications, tin is currently instrumental in the manufacture of tin solder, tin plate, alloys, and a spectrum of chemical products. Industries ranging from electronics, electrical appliances, and information technology to chemical, metallurgical, and aerospace depend on tin for its unique characteristics.

Navigating the Development Landscape of the Recycled Tin Industry

As a heavy metal with scarcity and expense attached, tin faces a dual challenge – increasing global consumption and diminishing natural resources. In response, the recycled tin industry emerged as a beacon of sustainability. Not only does it supplement the depletion of original tin mineral resources, but it also champions energy conservation, environmental protection, and cost reduction in industrial production.

The recycled tin industry commands attention globally, contributing over 60% to the original tin output in developed countries. Leading this charge are industrialized nations such as the United States, Britain, Germany, and Japan, highlighting the worldwide significance of recycled tin.

Unveiling the Sources and Recycling Methods of Tin

Tin is sourced directly from concentrates, referred to as primary tin, and through the recycling of tin-containing waste – a process known as recycled tin. This section takes a comprehensive look at the utilization of recycled tin resources, including tin-associated ore, paragenetic ore, tailings, slag, and other waste materials.

Exploring Tin Scrap Varieties

Examining various forms of tin waste, such as tin slag, gray tin, tin wire, solder paste, and silver tin, this section underscores the importance of recycling these materials. Not only does it contribute to sustainable resource management, but it also aligns with the global effort to reduce waste and environmental impact.

The Rise of Tin Tailings Recycling

As traditional tin ore resources decline, tin mine tailings gain prominence. With the aid of modern beneficiation technology, especially in fine ore dressing and low-tin smelting, the reclamation of tin tailings has accelerated. Tin tailings are emerging as a valuable resource in the recycling of tin, presenting a sustainable solution to depleting ore reserves.

Tackling Tinplate Waste Challenges

Waste tinplate, a substantial source of recycled tin, deserves special attention. Originating from tin-plated thin steel, this waste stream is critical in the recycling process. With a global consumption of 18 million tons annually, tinplate waste poses both challenges and opportunities in the quest for sustainable tin resource management.

Conclusion

In conclusion, the recycling journey of tin is not merely an industrial necessity but a sustainable imperative. Stanford Advanced Materials recognizes the pivotal role of recycling in ensuring the longevity of tin resources. As the world continues to rely on tin for technological advancements, the recycled tin industry stands as a beacon of innovation, providing a sustainable solution to meet the demands of a growing economy.