How Bronze is Used Today

Introduction

Bronze, the pioneering metal alloy, has a rich history and continues to play a crucial role in various applications today. This article explores the unique properties of bronze, its composition, and its relevance in contemporary uses. As we delve into the world of metal alloys, Stanford Advanced Materials stands as a leading provider, contributing to advancements in materials science.

Composition of Bronze

Bronze stands as a testament to the successful combination of copper and tin, with additional possibilities of incorporating metals like arsenic, antimony, or lead. Unlike a compound, bronze is a mixture of elements, offering flexibility in adjusting proportions based on specific requirements.

Properties of Bronze

In comparison to its parent metals, copper and tin, bronze boasts distinctive properties that make it indispensable in various applications. The enhanced hardness of bronze renders it valuable for crafting tools and weapons, and its ability to be sharpened further expands its utility. Additionally, the lower melting point of bronze in comparison to pure copper facilitates smoother casting, reducing the likelihood of trapped bubbles and resulting in a harder final product.

Microscopic Insight

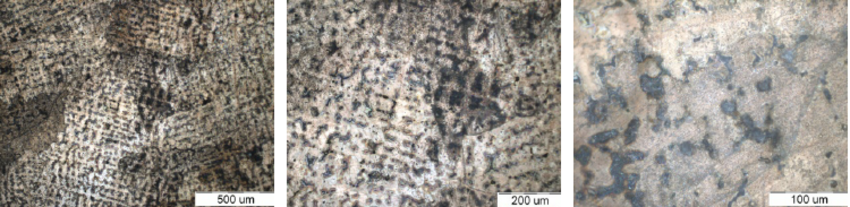

The microscopic structure of bronze provides valuable insights into its unique characteristics. The incorporation of small amounts of tin into the copper lattice as substitutional impurities reinforces the metal. The larger size of tin atoms hinders the slippage of planes of atoms, reducing the overall flexibility of the material. Furthermore, increased tin content creates precipitates with a distinct crystal structure, reinforcing the metal and making it resistant to slippage. The widely embraced ratio of 10% tin in copper exemplifies the optimal balance that yields excellent properties. Despite its advantages, it's essential to note that the inhomogeneous crystal lattice of bronze alloys results in lower electrical conductivity compared to pure copper.

Figure 1. Microscopic structure of bronze used for electrochemical studies: a) x100; b) x200; c) x500 [1]

Applications of Bronze Today

Bronze, with its unique combination of properties, finds a myriad of applications in the modern world. While it may not be as prevalent as it once was during the Bronze Age, its distinct qualities make it indispensable in various fields.

Art and Sculpture:

Bronze's malleability and ability to capture intricate details make it a preferred material for artists and sculptors. Many famous sculptures, including iconic statues and art pieces, are crafted from bronze due to its durability and aesthetic appeal.

Architectural Ornamentation:

Architectural elements, such as ornate doors, gates, and decorative features, often incorporate bronze. Its corrosion resistance ensures that these structures maintain their artistic beauty over time, even in outdoor environments.

Marine Applications:

Bronze's resistance to corrosion, especially in seawater, makes it a valuable material for marine applications. It is used in crafting propellers, ship fittings, and underwater components where other metals might succumb to the corrosive effects of saltwater.

Musical Instruments:

Bronze alloys are commonly used in the manufacturing of musical instruments, producing a distinct and resonant sound. Cymbals, bells, and certain parts of string instruments benefit from the acoustic properties of bronze.

Bearings and Bushings:

The hardness and wear resistance of bronze makes it suitable for creating durable bearings and bushings. In machinery and automotive applications, bronze components provide reliable and long-lasting performance.

Coinage:

While modern coins are typically made of other materials, historically, bronze played a significant role in coinage. Its durability and resistance to wear made it an excellent choice for producing long-lasting currency.

Electrical Components:

Bronze's conductivity makes it valuable in electrical applications. It is used in the production of connectors, switches, and other electrical components where a balance of electrical conductivity and mechanical strength is crucial.

Medals and Awards:

Bronze continues to be a popular choice for crafting medals and awards due to its ability to maintain its appearance over time. Its luster and durability contribute to the prestigious nature of such recognitions.

Conclusion

In conclusion, bronze's journey from ancient times to the present showcases its adaptability and enduring significance. The alloy's distinctive properties, coupled with the expertise of institutions like Stanford Advanced Materials, propel it into the forefront of materials science. As we look towards the future, bronze stands as a testament to the timeless fusion of innovation and tradition.

Reference:

1. Chelaru, Julieta & Barbu-Tudoran, Lucian & Muresan, Liana. (2013). Protection of artistic bronzes by artificial patina and wax. Studia Universitatis Babes-Bolyai Chemia. 58. 173-182.