List of Low Temperature Superconducting Material

Introduction

Low-temperature superconducting materials, characterized by a critical temperature (Tc) below 30K, operate in the frigid realms of liquid helium. This class of materials encompasses metals, alloys, and compounds, each contributing to unique applications in various fields. In this article, we delve into the world of low-temperature superconductors, highlighting notable materials and their practical applications.

Low-temperature Superconducting Metals

The foremost player in this category is niobium (Nb), a low-temperature superconducting metal of significant practical value. Often transformed into thin film materials for applications in weak electricity, superconducting niobium rods, particularly in the beta phase solid solution, exhibit a Tc above 9K. The versatility of niobium has paved the way for advancements in weak electric components.

Alloy Advancements

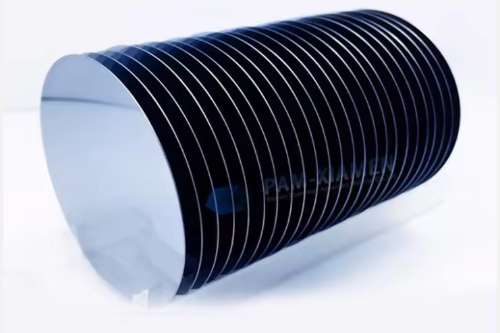

The evolution of low-temperature superconducting materials saw the emergence of NbZr alloy, succeeded by the superior NbTi alloy. NbTi alloy dominates approximately 95% of low-temperature superconducting alloys, boasting enhanced superconductivity and processing properties. Its applications range from traditional metal processing methods to the innovative multi-core composite machining method, resulting in the creation of efficient superconductor matrices.

Compounds in Focus

Key compounds in the low-temperature superconducting realm include NbN (Tc=16K), Nb3Sn (Tc=18.1K), and V3Ga (Tc=16.8K). NbN, often utilized in thin film form, showcases remarkable stability, making it an ideal choice for practical weak electric components. Nb3Sn, despite its brittleness, finds applications in high-field magnets and magnet-controlled nuclear fusion devices.

Applications in Various Fields

The versatile applications of low-temperature superconducting materials extend across diverse fields. NbTi superconducting material finds its place in high-energy physics accelerators, plasma magnetic confinement, superconducting motors, and magnetic resonance imaging instruments. Nb3Sn, aside from producing small high-field magnets, contributes to the creation of magnet-controlled nuclear fusion devices.

Challenges and Future Prospects

The limitations of low Tc values necessitate the use of these materials at liquid helium temperatures, resulting in high operational costs. Despite this challenge, the unique property of superconductors—minimal electrical resistance—continues to drive advancements in superconducting technology. Ongoing developments in material science aim to optimize the performance of superconducting materials, pushing the critical temperature higher and expanding their practical applications.

Conclusion

In the realm of low-temperature superconducting materials, the interplay of metals, alloys, and compounds has unlocked a myriad of applications across scientific, medical, and military domains. As we navigate the frigid landscapes of liquid helium, the quest for higher critical temperatures and more cost-effective operational methods propels the field forward. Stanford Advanced Materials remains at the forefront of these innovations, contributing to the evolution of low-temperature superconducting materials and their diverse applications.