Are Rare Earth Metals Important?

1. Introduction

Rare earth metals, a group of 17 elements encompassing 15 lanthanides along with scandium and yttrium, have long been shrouded in mystery and misconceptions. This article aims to unravel the importance of rare earth metals by delving into their definition, debunking the myth of scarcity, and exploring their critical role across various industries.

Definition of Rare Earth Metals by IUPAC

The International Union of Pure and Applied Chemistry (IUPAC) categorizes rare earth metals as a distinct set of elements, comprising 15 lanthanides, scandium, and yttrium. Understanding this classification provides a foundation for comprehending the unique properties and applications of these elements.

Dispelling the Myth of Scarcity

Contrary to popular belief, rare earth metals are not as scarce as the name implies. They are present in abundance within the Earth's crust. However, their dispersion and unique geochemical properties make their extraction and utilization a complex endeavor. Dispelling the myth of scarcity is crucial to recognizing the true potential and significance of these elements.

Importance of Rare Earth Metals in Various Industries

The importance of rare earth metals extends far beyond their prevalence or scarcity. These elements play a pivotal role in numerous industries, contributing to advancements in technology, energy, and defense. To comprehend their significance fully, it is essential to explore their applications across diverse sectors, from high-tech gadgets to national defense systems.

As we journey through the intricate landscape of rare earth metals, we will uncover their ubiquity, delve into their applications, and assess their impact on global industries. Are rare earth metals truly important? Let's unravel the layers that surround these elements and reveal the critical role they play in shaping the world as we know it.

2. The Ubiquity of Rare Earth Metals

Rare earth metals, though often perceived as elusive, are remarkably ubiquitous, scattered throughout the Earth's crust in varying concentrations. Understanding their distribution, geochemical properties, and the distinctive composition of the 17 elements, including lanthanides, scandium, and yttrium, is crucial to appreciating their prevalence and significance.

Presence in the Earth's Crust

Contrary to their name, rare earth metals are anything but rare in the Earth's crust. These elements can be found in measurable quantities across the globe, with some regions exhibiting higher concentrations than others. The challenge lies not in their scarcity but in their widespread dispersion, making extraction and processing a nuanced task.

Exploring the geological aspects of their presence sheds light on the diverse ecosystems where these metals are embedded. This insight aids in understanding the variations in their accessibility and the environmental considerations associated with extraction.

Geochemical Properties Leading to Dispersion

The geochemical properties of rare earth metals contribute significantly to their dispersion. Unlike some elements that aggregate in concentrated deposits, rare earth metals tend to disperse broadly, often coexisting with other minerals. This dispersion is a result of their similar chemical behaviors, complicating the extraction process.

As we unravel the intricacies of their geochemistry, it becomes evident that the challenge in harnessing the full potential of rare earth metals lies not just in their quantity but in their scattered nature. Innovative extraction methods and sustainable practices become imperative in navigating these challenges and ensuring a stable supply for various industries.

Explanation of the 17 Elements

To comprehend the ubiquity of rare earth metals, it is essential to delve into the classification of the 17 elements that constitute this group. The lanthanides, ranging from cerium to lutetium, form the backbone of this category. Additionally, scandium and yttrium, though distinct from the lanthanides, share similarities in their chemical properties, contributing to the comprehensive nature of rare earth metals.

Understanding the unique characteristics of each element is vital for unlocking their diverse applications. From the magnetic properties of neodymium to the luminescence of europium, each element brings distinctive qualities to the table, shaping their roles in various industries.

In the subsequent sections, we will explore the applications of rare earth metals in-depth, shedding light on their crucial roles in high-tech gadgets, electronic fields, and even national defense. By unraveling the ubiquity of these elements, we pave the way for a comprehensive understanding of their importance and impact on our modern world.

3. Industrial Applications

Rare earth metals have become the unsung heroes behind the scenes, powering the very fabric of our technological landscape. Their applications span across a multitude of industries, from high-tech gadgets to military technology, shaping the modern world in ways often unnoticed.

High-Tech Gadgets and Military Technology

Rare earth metals are the backbone of innovation in high-tech gadgets and military advancements. These elements, with their unique properties, contribute significantly to the development of cutting-edge technologies that define our era.

Electronic and Electrical Fields

Rechargeable Batteries

Rare earth metals, particularly lanthanum, cerium, and neodymium, play a crucial role in the development of rechargeable batteries. These batteries, powering devices from electric vehicles to portable electronics, rely on the high energy density and stability provided by these elements.

Computer Memory

In the realm of computing, rare earth metals find their place in the development of computer memory. The magnetic properties of neodymium, for example, contribute to the creation of stable and high-capacity memory storage.

Cell Phones

The ubiquity of cell phones in our daily lives is indebted to rare earth metals. From the vibrant colors of the display (courtesy of europium) to the compact and powerful magnets inside speakers (thanks to neodymium), these elements are integral to the functionality and aesthetics of our devices.

DVDs

Europium and terbium, among other rare earth metals, contribute to the creation of vivid colors in the phosphors of DVDs. This ensures a visual experience that is both immersive and technologically advanced.

Magnets

Neodymium, a rare earth metal, is a key component in the creation of powerful magnets. These magnets, known as neodymium magnets, are utilized in various applications, from electric motors to headphones.

Car Catalytic Converters

Rare earth metals, particularly cerium, find applications in catalytic converters in automobiles. These converters help reduce harmful emissions, contributing to environmental sustainability.

Increasing Global Demand for Electronic Devices

Impact on Rare Earth Element Supply

The increasing global demand for electronic devices has a direct impact on the supply of rare earth elements. As the consumption of high-tech gadgets rises, the need for a stable supply of these elements becomes more pressing.

Necessity for Fulfilling Demand in Various Industries

Beyond consumer electronics, rare earth metals are essential in various industries such as aerospace, healthcare, and renewable energy. The necessity to fulfill the demand for these elements extends beyond convenience to encompass critical sectors that drive progress and sustainability.

As we explore the industrial applications of rare earth metals, it becomes evident that these elements are not mere components but the linchpin holding together the intricate tapestry of our technologically advanced world. The surge in global demand necessitates a closer examination of the extraction, supply chain, and sustainable practices to ensure a harmonious balance between innovation and resource stewardship.

4. Diverse Industrial Uses

Rare earth metals, often associated with electronics and high-tech gadgets, extend their influence across diverse industrial sectors. Their unique properties make them indispensable in applications ranging from refining processes to the production of permanent magnets, highlighting their versatility and significance in modern industry.

Petroleum Refining

Rare earth metals, particularly cerium, find application in petroleum refining processes. Cerium-based catalysts assist in refining crude oil, enhancing the efficiency of various refining reactions and reducing environmental pollutants.

Glass Polishing

The precision required in optics and glass manufacturing calls for the use of rare earth metals. Lanthanum oxide, for instance, is employed in the polishing process, contributing to the production of high-quality lenses and optical components.

Chemical Catalysts

Rare earth metals act as catalysts in various chemical processes. Their ability to facilitate reactions at lower temperatures and with increased efficiency makes them valuable in the production of chemicals, pharmaceuticals, and other industrial compounds.

Metallurgy

In the field of metallurgy, rare earth metals play a pivotal role in refining and enhancing the properties of metals. These elements are used as alloying agents, contributing to the strength, durability, and heat resistance of metals.

Catalytic Converters

While catalytic converters in automobiles were previously mentioned in the context of electronic devices, their significance extends to the broader domain of environmental sustainability. Rare earth metals, such as cerium and lanthanum, help catalyze reactions that convert harmful pollutants in exhaust gases into less harmful substances.

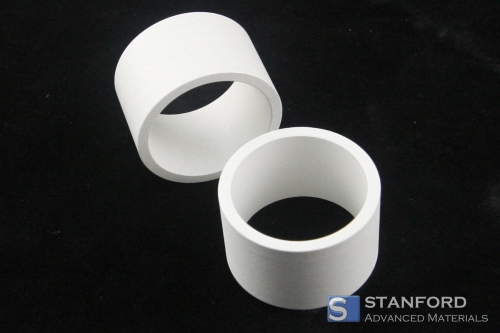

Permanent Magnet Production

The production of powerful permanent magnets, crucial in various applications, heavily relies on rare earth metals. Neodymium and samarium-cobalt magnets, both containing rare earth elements, are integral to the manufacturing of motors, speakers, and a myriad of electronic devices.

Television and Monitors

Rare earth metals find their way into the world of visual technology. Europium, for instance, is employed in the creation of phosphors for television and monitor screens, contributing to the vibrant and colorful displays we encounter daily.

The diversity of industrial uses underscores the far-reaching impact of rare earth metals. From refining processes to environmental solutions and advanced manufacturing, these elements serve as catalysts for progress across a spectrum of industries. As we appreciate their multifaceted applications, it becomes clear that the importance of rare earth metals transcends the boundaries of technology and extends into the very fabric of industrial innovation and sustainability.

5. Specialized Applications

Beyond their conventional uses in electronics and metallurgy, rare earth metals showcase their versatility in specialized applications, contributing to industries that rely on precision, clarity, and environmental stewardship.

Importance in Industries Using Phosphors, Catalysts, and Polishing Compounds

Phosphors:

Rare earth metals, particularly europium and terbium, are essential in the production of phosphors. These phosphors are widely used in industries that require illuminating screens, such as those found in televisions, monitors, and electronic displays. The luminescent properties of these elements enhance the visual experience and color accuracy.

Catalysts:

The catalytic properties of rare earth metals make them indispensable in various industries. They serve as catalysts in chemical processes, facilitating reactions with precision and efficiency. Their use in catalysts extends to applications in the production of fuels, chemicals, and pharmaceuticals, highlighting their importance in driving industrial processes.

Polishing Compounds:

Lanthanum oxide, a rare earth oxide, is frequently employed in the manufacturing of polishing compounds. These compounds play a crucial role in the production of optical lenses, precision instruments, and glass components. The use of rare earth metals in polishing ensures the creation of surfaces with exceptional clarity and quality.

Use in Illuminating Screens and Optical Quality Glass

Illuminating Screens:

Rare earth metals, particularly europium, and terbium, contribute to the creation of illuminating screens. The phosphors containing these elements emit light when exposed to electrons, producing vibrant and accurate colors. This technology is extensively utilized in the production of television screens, computer monitors, and electronic displays.

Optical Quality Glass:

Lanthanum oxide, with its ability to enhance optical properties, is incorporated into the manufacturing of optical-quality glass. This type of glass is crucial for lenses, camera components, and precision optics. The inclusion of rare earth metals ensures the production of glass with minimal distortions and superior clarity.

Air Pollution Control Applications

Rare earth metals play a pivotal role in addressing environmental challenges, particularly in the domain of air pollution control.

Catalytic Converters:

As mentioned earlier in the context of automotive applications, rare earth metals, including cerium and lanthanum, are essential components in catalytic converters. These devices help mitigate air pollution by catalyzing the conversion of harmful emissions into less harmful substances.

Phosphors for Air Pollution Control:

Rare earth metals find application in the creation of phosphors used in air pollution control devices. These phosphors, when exposed to ultraviolet light, can break down pollutants, contributing to the reduction of air pollution in industrial settings.

As we navigate the specialized applications of rare earth metals, it becomes evident that their impact extends beyond the realms of consumer electronics. These elements play a vital role in shaping industries that prioritize precision, visual clarity, and environmental responsibility. In doing so, rare earth metals emerge not only as technological enablers but as contributors to a more sustainable and advanced industrial landscape.

6. Conclusion

Rare earth metals, often overlooked in their ubiquity, emerge as silent protagonists shaping the technological, industrial, and environmental landscapes. As we conclude this exploration, it's essential to recap their importance, advocate for awareness and sustainable practices, and consider the future prospects and ongoing research in alternative technologies.

Recap of the Importance of Rare Earth Metals

In recapping the importance of rare earth metals, it is clear that these elements serve as linchpins in the modern world's intricate machinery. From high-tech gadgets and military advancements to diverse industrial applications, rare earth metals are the unsung heroes enabling progress and innovation. Their unique properties make them irreplaceable in numerous sectors, from electronics to air pollution control, contributing to advancements that touch every aspect of our daily lives.

The myth of scarcity is dispelled, revealing that the challenge lies not in their abundance but in their dispersed nature. Recognizing the geological, chemical, and industrial aspects of rare earth metals provides a comprehensive understanding of their true significance.

Call for Awareness and Sustainable Practices

With this newfound understanding, a crucial call for awareness and sustainable practices emerges. The extraction and processing of rare earth metals come with environmental challenges, including habitat disruption and chemical pollution. By fostering awareness about responsible sourcing, recycling practices, and the environmental impact of extraction, we pave the way for a more sustainable future.

Awareness extends not only to consumers but also to industries, policymakers, and researchers. Collaborative efforts are essential to develop and implement sustainable practices that ensure the responsible use of rare earth metals, minimizing ecological footprints and mitigating potential environmental harm.

Future Prospects and Research in Alternative Technologies

Looking ahead, the future of rare earth metals intertwines with ongoing research in alternative technologies. Scientists and engineers worldwide are exploring substitutes, recycling methods, and more sustainable extraction processes to reduce dependence on these elements. The development of eco-friendly technologies that limit reliance on rare earth metals is a promising avenue, ensuring a more balanced and resilient technological ecosystem.

In conclusion, the importance of rare earth metals transcends their current applications. They are catalysts for progress, innovation, and environmental solutions. As we navigate the delicate balance between technological advancement and environmental stewardship, a conscientious approach to the use of rare earth metals becomes paramount. By fostering awareness, embracing sustainable practices, and investing in alternative technologies, we can secure a future where the significance of these elements is harmoniously integrated into a sustainable and thriving global landscape.