What Are the Uses of Cobalt?

Cobalt, with its chemical symbol Co and atomic number 27, is a metal of multifaceted utility. Often referred to as the "industrial monosodium glutamate" and the "industrial tooth," cobalt is a precious yet scarce metal, earning its status as one of the crucial strategic resources.

This metal primarily emerges from copper-cobalt ore, nickel-cobalt ore, arsenic-cobalt ore, and pyrite deposits, with scant independent cobalt minerals. Interestingly, seabed manganese tuberculosis presents a promising, long-term reservoir of cobalt, adding a unique dimension to its sourcing.

Cobalt's Traditional Domains of Influence

Cobalt finds itself deeply embedded in various sectors, showcasing its indispensability across diverse applications. Its primary areas of consumption include battery materials, super heat-resistant alloys, tool steels, hard alloys, and magnetic materials.

Battery Materials

In the realm of battery materials, cobalt plays a pivotal role in lithium-ion batteries, enhancing energy density and performance. The cobalt oxide cathodes contribute significantly to the efficiency and longevity of lithium-ion batteries, driving advancements in portable electronics and the electric vehicle revolution.

Super Heat-Resistant Alloys

The influence of cobalt extends to super heat-resistant alloys, where its exceptional heat resistance and stability make it a crucial component. In industries such as aerospace, cobalt alloys ensure the structural integrity of components, such as turbines and aircraft engines, under extreme temperatures.

Tool steels

In the realm of tool steels, cobalt adds an edge – quite literally. Cobalt-infused tool steels exhibit superior hardness and wear resistance, making them ideal for cutting tools, drills, and other applications where durability and precision are paramount. This characteristic has led to widespread use in machining, mining, and construction industries, enhancing the efficiency and longevity of cutting and drilling equipment.

Hard alloys

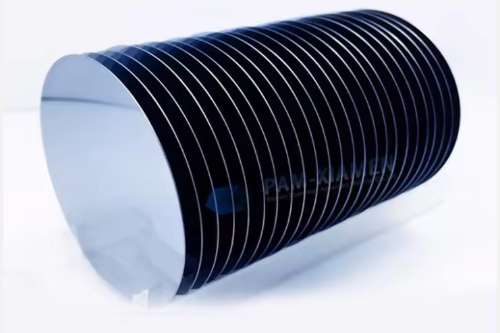

Hard alloys, another domain where cobalt shines, find applications in a myriad of industries. Cemented carbides, composed of tungsten carbide particles embedded in a cobalt matrix, are extensively used in cutting tools, wear-resistant parts, and mining equipment. The amalgamation of tungsten carbide and cobalt creates a material that can withstand the harsh conditions of machining, drilling, and mining, exemplifying cobalt's versatility in demanding industrial settings.

Magnetic Materials

Cobalt's magnetic allure is not limited to traditional applications. Its presence is crucial in the development of cutting-edge magnetic materials with applications ranging from data storage to medical imaging. As industries transition to more advanced technologies, cobalt remains at the forefront, ensuring the efficiency and reliability of magnetic components integral to these innovations.

Pioneering the Radiant Path: Cobalt-60's Radiological Influence

Cobalt-60, a widely utilized radioactive material, stands out for its applications in biochemistry through activation analysis and medical treatments. In biochemistry, activation analysis involving Cobalt-60 serves as a powerful tool for determining the elemental composition of materials and finding applications in environmental monitoring, quality control, and forensic analysis.

In the medical field, Cobalt-60 extends beyond diagnostic radiological examinations to treatments. Employed in radiation therapy for cancer treatment, its high-energy gamma rays target and destroy cancer cells. The controlled and precise nature of Cobalt-60 radiation therapy has revolutionized cancer treatment, offering an effective and focused approach to combating this challenging disease.

Cobalt in the Aerospace Stratosphere

Cobalt's inherent qualities – high-temperature resistance, corrosion resistance, and magnetic prowess – propel its extensive use in aerospace applications. From crafting cutting-edge components to influencing machinery design, cobalt has become an integral part of the aerospace industry.

In aerospace applications, where extreme conditions define the environment, cobalt's resilience becomes particularly valuable. Components subjected to high temperatures, such as jet engines and gas turbines, benefit from the high-temperature stability of cobalt alloys, ensuring the reliability and safety of aerospace systems.

Machinery manufacturing represents another frontier where cobalt's influence is deeply ingrained. Cobalt's contribution to the production of cutting tools, machine parts, and precision instruments is vital in enhancing the efficiency and durability of manufacturing processes. The use of cobalt alloys in critical components, such as gears and bearings, ensures optimal performance and longevity, contributing to the overall reliability of machinery.

In the electrical and electronic sectors, cobalt's magnetic properties come to the forefront. Magnetic materials, including those used in transformers, electric motors, and electronic devices, leverage cobalt's unique characteristics to achieve desired performance levels. The precision and stability offered by cobalt-based magnetic materials contribute to the efficiency and reliability of electrical systems, further solidifying cobalt's role in modern electronics.

Chemical processes benefit from cobalt's catalytic prowess, where it acts as a catalyst in various reactions. Catalytic converters in automobiles, for example, often contain cobalt-based catalysts that facilitate the conversion of harmful gases into less toxic substances. This application not only contributes to environmental protection but also underscores cobalt's role in sustainable technologies.

Ceramic production, an industry reliant on materials with specific properties, finds a valuable ally in cobalt. Cobalt pigments, known for their vibrant and stable colors, are widely used in the production of ceramics, glass, and enamels. The aesthetic appeal and durability imparted by cobalt pigments contribute to the artistic and functional aspects of ceramics, enhancing their value in various applications.

Cobalt's Role in Advancing Technologies and the Future

As industries evolve and technological landscapes shift, cobalt continues to carve its path through uncharted frontiers. Its role in energy storage, catalysis, and magnetic technologies positions it as a key player in shaping the future. Ongoing research and innovation hold the promise of unlocking even more applications, underscoring cobalt's status as a cornerstone element in the ever-expanding world of materials science.

In conclusion, the uses of cobalt extend far beyond its industrial moniker. From its foundational role in aerospace to its magnetic marvels, cobalt is a vital force driving innovation across sectors. As we delve deeper into the realms of materials science and technological advancement, the story of cobalt unfolds, revealing a narrative of versatility, indispensability, and endless potential.