Factors Affecting the Service Life of Molybdenum Electrodes

The glass industry is a traditional industry with high energy consumption. With the high price of fossil energy and the improvement of environmental protection requirements, melting technology has changed from traditional flame heating technology to electric melting technology. The electrode is the element that contacts directly with the glass liquid and passes the electrical energy to the glass liquid, which is the important equipment in the glass electrofusion.

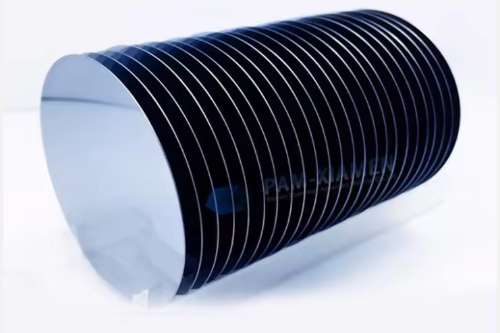

Molybdenum electrode is an indispensable electrode material in glass electrofusion because of its high-temperature strength, corrosion resistance, and the difficulty in making glass coloring. It is hoped that the service life of the electrode will be as long as the kiln age or even more than the age of the kiln, but the electrode will often be damaged during the actual use. It is of great practical significance to fully understand the various influencing factors of the service life of molybdenum electrodes in glass electro-fusion.

Oxidation of the Molybdenum Electrode

The molybdenum electrode has the characteristics of high-temperature resistance, but it reacts with oxygen at high temperatures. When the temperature reaches 400 ℃, the molybdenum will begin to form molybdenum oxidation (MoO) and molybdenum disulfide (MoO2), which can adhere to the surface of the molybdenum electrode and form an oxide layer, and organize the further oxidation of molybdenum electrode. When the temperature reaches 500 ℃ ~ 700 ℃, molybdenum will start oxidizing to molybdenum trioxide (MoO3). It is a volatile gas, which destroys the protective layer of the original oxide so that the new surface exposed by the molybdenum electrode continues to oxidize to form MoO3. Such repeated oxidation and volatilization make the molybdenum electrode continuously eroded until it is completely damaged.

The reaction of the Molybdenum Electrode to The Component in the Glass

The molybdenum electrode reacts with some components or impurities in the glass component at high temperatures, causing serious erosion of the electrode. For example, the glass solution with As2O3, Sb2O3, and Na2SO4 as the clarifier is very serious for the erosion of the molybdenum electrode, which will be oxidized to MoO and MoS2.

Electrochemical Reaction in Glass Electrofusion

The electrochemical reaction occurs in the glass electrofusion, which is at the contact interface between the molybdenum electrode and the molten glass. In the positive half cycle of the AC power supply, negative oxygen ions are transferred to the positive electrode to release electrons, which release oxygen to cause the oxidation of the molybdenum electrode. In the AC power supply negative half cycle, some of the glass melt cations (such as boron) will move to the negative electrode and the generation of molybdenum electrode compounds, which are loose deposits in the electrode surface to damage the electrode.

Temperature and current density

The erosion rate of molybdenum electrode increases with the increase of temperature. When the glass composition and process temperature are stable, the current density becomes the factor controlling the corrosion rate of the electrode. Although the maximum allowable current density of molybdenum electrode can reach 2~3A/cm2, the electrode erosion will be increased if the large current is running.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the factors affecting the service life of molybdenum electrodes. If you want to learn more about molybdenum alloys, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

Stanford Advanced Materials (SAM) is a worldwide molybdenum supplier and has over two decades of experience in the manufacture and sale of molybdenum products, providing high-quality products to meet our customers' R&D and production needs. As such, we are confident that SAM will be your favorite molybdenum supplier and business partner.