Maintenance Techniques of Platinum-rhodium Thermocouple

Platinum-rhodium thermocouples are critical components in many industrial processes, known for their ability to accurately measure high temperatures. These devices, typically made from precious metal alloys, represent a significant investment due to the costliness of materials like platinum and rhodium. Proper maintenance is essential not only to ensure the accuracy and reliability of these thermocouples but also to extend their service life, thereby optimizing production costs. Here, we explore some of the essential maintenance techniques for platinum-rhodium thermocouples.

Routine Cleaning and Maintenance

Pickling

Pickling is a crucial maintenance step that involves using the oxidative capacity of acids to remove organic contaminants and other impurities that can accumulate on the surface of the thermocouple. To perform pickling:

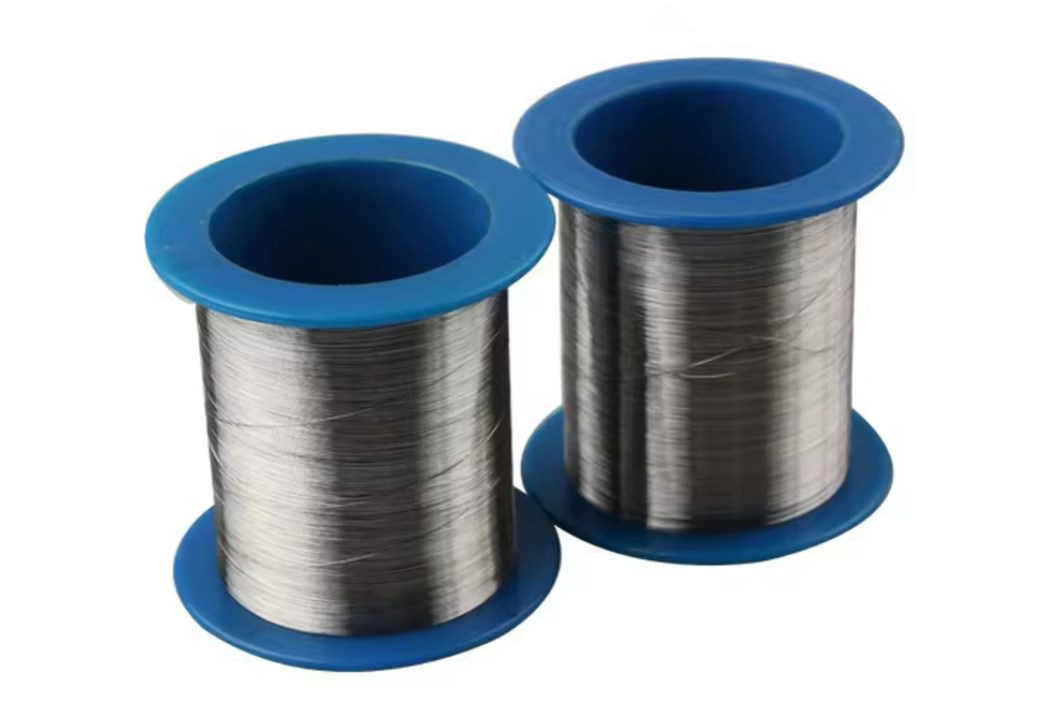

- Shape the platinum-rhodium thermocouple into a coil approximately 80mm in diameter.

- Place the coil in a beaker and immerse it in a 30 to 50 percent solution of chemically pure dilute hydrochloric acid or nitric acid.

- Allow the thermocouple to soak for about an hour.

- After soaking, transfer the thermocouple to a clean beaker and rinse it multiple times with distilled water by boiling. This step ensures the complete removal of acid residues, thereby preventing corrosion or further contamination.

Sodium Borate Removal

Following pickling, the thermocouple should undergo a sodium borate cleaning process to remove any residual metals or oxides that are insoluble in the acid used during pickling. The steps include:

- Suspend the cleaned thermocouple on a platinum wire within an annealing ark.

- Adjust the electric current to heat the thermocouple to 1100 °C.

- Gently touch the hot part of the thermocouple with a lump of sodium borate, allowing the resulting boric acid solution to flow down and cleanse the electrode.

- Gradually reduce the current to cool the thermocouple.

- Finally, place the thermocouple back into a beaker and boil in distilled water several times to fully remove any borate residues.

Annealing

Annealing is a process designed to relieve internal stresses within the thermocouple's electrodes and to stabilize the crystal phase of the metals. This process is vital for maintaining the accuracy of the thermocouple's temperature readings and can be conducted using one of two methods:

- Electric Annealing: Directly heat the thermocouple using an electric current until it reaches the desired annealing temperature, then maintain this temperature for a predetermined period before allowing the thermocouple to cool gradually.

- Furnace Annealing: Place the thermocouple in a furnace set to the desired temperature. Maintain the temperature for a suitable duration to achieve effective stress relief and phase stabilization.

Conclusion

Maintaining platinum-rhodium thermocouples involves a series of precise and careful procedures to ensure their longevity and reliability. Regular pickling, thorough cleaning with sodium borate, and careful annealing are crucial to preserving the functional integrity of these expensive instruments. By adhering to these maintenance techniques, industries can maximize the lifespan of their thermocouples, thereby safeguarding their investments and maintaining the efficiency of their temperature measurement processes. This proactive approach to maintenance not only reduces the likelihood of premature failure but also ensures the continued accuracy and reliability of the temperature data crucial for quality control in high-temperature applications.