The Overview of Nanomaterials

A brief history of nano development

In 1959, the famous physicist and Nobel Prize winner Richard Feynman predicted that humans could use smaller machines to make even smaller machines, and eventually to arrange the atoms one at a time and make products one at a time according to human wishes, which was the earliest dream of nanotechnology. was the earliest dream of nanotechnology.

In 1991, scientists in the United States successfully synthesized carbon nanotubes and found that they were only one-sixth of the mass of the same volume of steel and ten times as strong, so it's called super fiber. The discovery of nanomaterials marks a new high in the discovery of material properties. In 1999, annual turnover of the nano products reached $50 billion.

What is the nanomaterial?

The nanometer (nm) is a unit of length, and one nanometer is 10-9 meters (billionth of a meter). For macroscopic matter, the nanometer is a very small unit. The diameter of human hair is generally 7000-8000nm, while the human red blood cells are generally 3,000-5000nm, and the general virus is also dozens to hundreds of nanometers, and the grain size of metal is generally in the micron scale. For the microscopic matter like atoms, molecules, and so on, which used to be expressed as an angstrom, an angstrom is the diameter of a hydrogen atom, and a nanometer is 10 angstrom.

It is generally believed that nanomaterials should include two basic conditions: one is that the characteristic size of nanomaterials is between 1 and 100nm, and the other is that nanomaterials have some special physical and chemical characteristics that distinguish normal sized materials at this time.

Nanomaterials refer to materials that are at least one dimension at the nanometer size (0.1-100 nm) in the three-dimensional space or composed of them as basic units, which is about the size of 10 to 100 atoms closely packed together. Currently, nanomaterials have the following applications.

Natural nanomaterial

Sea turtles lay their eggs near the coast of Florida in the United States. However, the baby turtles after birth have to swim to the waters near the UK to survive and grow up in search of food. Eventually, the adults return to Florida's coast to lay eggs. It takes about five to six years to go back and forth. Why are turtles able to travel tens of thousands of kilometers? In fact, they rely on nanomagnetic materials inside their heads to navigate them correctly.

Biologists studying why creatures like pigeons, dolphins, butterflies, and bees never get lost have also found nanomaterials in their bodies to guide them.

Nanoscale magnetic materials

Most of the nanomaterials used in practice are artificial. Due to its small size, single domain structure and high coercivity, the magnetic recording material made of nanoparticle are not only better in sound quality, image, and signal-noise ratio, but also have a recording density dozens of times higher thanγ-Fe2O3. Superparamagnetic strong magnetic nanoparticles can also be made into magnetic liquids for the fields of electroacoustic devices, damping devices, rotary sealing, lubrication, and mineral dressing.

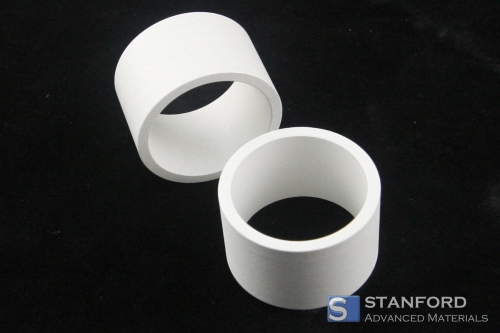

Nano ceramic material

The grain of traditional ceramic material is not easy to slide, the material is brittle and the sintering temperature is high, while nanoceramics have small grains that move easily over other grains. Therefore, nanoceramics have high strength, high toughness, and good ductility, which make nanoceramics materials can be processed cold at room temperature or under high temperature.

Nanosensor

Nano zirconia, nickel oxide, titanium dioxide, and other ceramics are very sensitive to temperature changes, infrared and automobile exhaust. As a result, they can be used to make temperature sensors, infrared detectors, and automobile exhaust detectors, with much higher detection sensitivity than common similar ceramic sensors.

Nano gradient functional materials

In aerospace hydrogen and oxygen engines, the inner surface of the combustion chamber needs to be resistant to high temperature and the outer surface must be in contact with the coolant. Therefore, the inner surface should be made of ceramics, while the outer surface should be made of metal with good thermal conductivity. However, lumpy ceramics and metals are hard to bond together. If the composition of the metal and ceramics is changed gradually and continuously during production, the metal and ceramics can be "connected with each other", eventually, they can be combined to form gradient functional materials. When the metal and ceramic nanoparticles are mixed and formed by sintering according to the requirement of their content gradually changing, it can meet the requirement of high-temperature resistance inside the combustion chamber and good thermal conductivity outside.

Nano semiconductor materials

The semiconductor materials such as silicon and gallium arsenide have many excellent properties. For example, the quantum tunneling effect in nano semiconductor makes the electron transport of some semiconductor materials abnormal, the conductivity decreases, and the thermal conductivity decreases as the particle size decreases, even the negative value appears. All of the above characteristics play an important role in the field of Lsi(Large Scale Integrated circuit)devices and optoelectronic devices. As the electrons and holes generated by nano-semiconductor particles under light irradiation have strong reduction and oxidation capacity, it can oxidize the toxic inorganic substances, degrade most organic substances, and eventually produce non-toxic, odorless carbon dioxide, water and so on. Therefore, semiconductor nanoparticles can be used to catalyze the decomposition of the inorganic and organic matter by solar energy.

Nano-catalytic material

Nanoparticles are an excellent catalyst. The nanoparticles are small in size, large in volume fraction on the surface, different in chemical bond state and electronic state on the surface, and incomplete in the coordination of atoms on the surface, resulting in the increase of active position on the surface, which makes it qualified as a catalyst.

The hydrogenation of nickel or copper-zinc nano-particles to some organics is an excellent catalyst and can replace expensive platinum or palladium catalysts. Nanometer catalyst platinum black can make ethylene oxidation reaction temperature reduced from 600 ℃ to room temperature.

Medical applications

Red blood cells in the blood are 6, 000 to 9, 000 nm in size, while nanoparticles are just a few nanometers in size, which is actually much smaller than red blood cells, so it can move freely in the blood. If a variety of therapeutic nanoparticles are injected into various parts of the body, they can be examined and treated, which is more effective than traditional injections and medicines.

Carbon materials are highly soluble in blood. In the 21st century, artificial heart valves are deposited on the material substrate with a layer of pyrolytic carbon or diamond-like carbon. However, this deposition process is complex and generally only applicable to the preparation of hard materials.

The interventional gasbag and catheter are generally prepared with a highly elastic polyurethane material. By introducing carbon nanotube materials with high length-diameter ratio and pure carbon atoms into polyurethane with high elasticity, we can make this polymer material maintain its excellent mechanical properties and easy to be processed and shaped, on the one hand, the better blood solubility can be obtained.

The results showed that the nanocomposite was less likely to cause hemolysis and less likely to activate platelets; the use of nano-technology can make the production process of drugs more and more refined, and directly use the arrangement of atoms and molecules on the scale of nano-materials to make drugs with specific functions; nanoparticles will make it easier for drugs to travel through the body, where smart drugs wrapped in layers of nanoparticles can actively search and attack cancer cells or repair damaged tissue; new diagnostic instruments using nanotechnology can detect diseases through proteins and DNA in a small amount of blood. The special properties of nanoparticles can be modified on the surface of nanoparticles to form some drug transport carriers with targeted, controllable release and easy detection, providing a new method for the treatment of local pathological changes in the body and opening up a new direction for drug development.

Nanomechanical computer

The world's first electronic computer was born in 1945, it is successfully developed jointly by American universities and the army, a sharing of the 18 000 tubes, the total weight of 30 t, covers an area of about 170 ㎡. It's a jumbo, but it can only do 5, 000 operations in 1 second.

After half a century, the development of integrated circuit technology, microelectronics, information storage technology, computer language, and programming technology has made rapid progress in computer technology. Today's computers are small enough to fit on a table. They weigh a tenth of a million times the weight of their predecessors, but they are much faster than the first electronic computers.

If nanotechnology is used to build the devices of electronic computers, the future computer will be a kind of "Molecular Computer". It is far more compact than today's computers and will bring considerable benefits to society in saving materials and energy.

Nanomaterial-class memory chips, which can read card readers on hard drives and hold thousands of times more memory than chips, are already in production. Computers can be shrunk to palmtop after widespread use of nanomaterials.

CNT (carbon nano-tube)

In 1991, Japanese experts produced the material called carbon nanotubes. It is a tube made of a number of hexagonal circular carbon atoms, or it can be made of several coaxial tubes. Both ends of the single-layer and multi-layer tube are often sealed, as shown here.

The diameter and tube length of this tube made of carbon atoms are all nanoscale, so it is called carbon nanotube. Its tensile strength is 100 times higher than that of steel and its conductivity is higher than that of copper.

Carbon nanotubes in air heated to 700 ℃ or so to make the pipe at the top of the pincer-like device of the carbon atom due to oxidation damage, became open carbon nanotubes. Then, the low-melting metal (such as lead) is evaporated by the electron beam and condensed on the open carbon nanotube. As a result of siphoning, the metal enters the hollow core of the carbon nanotube. Due to the extremely small diameter of carbon nanotubes, the metal wires formed inside the tubes are also very thin. They are called nanowires. Therefore, carbon nanotubes combined with nanowires may become new superconductors.

Nanotechnology is still in the embryonic stage in countries around the world. Although a few countries, such as the United States, Japan, and Germany, have begun to take shape, they are still in research, and new theories and technologies are still emerging.

Home appliances

The nano multi-functional plastic made of nanomaterials has the functions of antibacterial, deodorization, antisepsis, anti-aging, and anti-ultraviolet, which can be used as the antibacterial deodorization plastics in the shell of the refrigerator and air conditioner.

Environmental protection

There will be nano-membranes with unique functions in the field of environmental science. The membrane can detect pollution caused by chemical and biological agents and can filter those agents to eliminate pollution.

Textile industry

Nano-SiO2, nano-ZnO and nano-SiO2 composite powder materials are added to the synthetic fiber resin. After being drawn and woven, the underwear and garments can be made into sterilization, mildew prevention, deodorization, and ultraviolet radiation resistance. Besides, it can be used in the manufacture of anti-bacterial underwear, supplies, and can be manufactured to meet the requirements of the defense industry anti-ultraviolet radiation functional fiber.

Engineering industry

Nanopowder coating on the metal surface of key mechanical parts is applied to improve the wear resistance, hardness and service life of mechanical equipment.