An Overview of Various Ceramic Crucibles

Introduction

Crucibles, as pivotal components in chemical instruments, serve as vessels for melting, refining metal liquids, and facilitating the reaction of solids and liquids—an integral foundation for seamless chemical processes. Initially crafted from clay, the historical use of platinum for crucibles marked a significant technological stride. The evolution of preparation techniques now allows crucibles to be fashioned from diverse materials capable of withstanding melting or altering contents.

The myriad crucible types, models, and specifications offer unparalleled flexibility, ensuring the purity of melted materials. Among these, ceramic crucibles play a vital role. Categorized by raw materials, ceramic crucibles encompass quartz, corundum, boron nitride, zirconia, and more, each tailored for specific applications based on their distinctive properties.

1. Quartz Ceramic Crucible

A quartz ceramic crucible is crafted from highly pure fused quartz, featuring a fine structure, low thermal conductivity, a small thermal expansion coefficient, excellent thermal shock stability, good electrical performance, and chemical resistance. It finds wide application in the glass deep processing industry, metallurgy, electronics, chemicals, aerospace, and other fields. In general, the shape of the quartz ceramic crucible is mainly square and cylindrical.

With the attention and development of environmental protection energy, solar energy, as a green energy, has been widely valued in the world. The amount of polycrystalline silicon used for solar energy conversion has increased dramatically, thus promoting the rapid development of polycrystalline silicon production. Therefore, the corresponding large-size thin-walled square fused quartz ceramic crucible is also increasing rapidly, and the international market is very optimistic.

2. Corundum Crucible

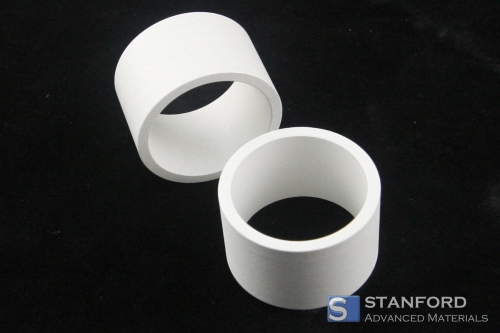

Corundum crucible, formally known as alumina crucible, is commonly referred to as corundum crucible when the content of alumina exceeds 95%. A corundum crucible is robust and can withstand high temperatures, acid, alkali, extreme cold and heat, and chemical corrosion. It is suitable for melting samples of weak alkaline substances like Na2CO3 without water. However, it is not suitable for melting samples with strong alkaline and acidic materials as fluxes.

99.70% of corundum crucible at oxidation and reduction atmosphere of 1650 ℃ to 1700 ℃ has good insulation and mechanical strength. According to the application conditions, the alumina crucible has a variety of sizes and shapes to choose from.

3. Boron Nitride Crucible

The commonly used types of boron nitride include cubic boron nitride (C-BN) and pyrolytic boron nitride (P-BN). The boron nitride crucible is usually composed of P-BN. P-BN ceramics have good heat resistance, thermal stability, thermal conductivity, and high-temperature dielectric strength, and are ideal heat dissipation materials and high-temperature insulation materials.

P-BN, known for its superb chemical stability, can resist erosion from most molten metals. It excels in high-temperature insulation, has high thermal conductivity, and a low thermal expansion coefficient. These properties make it ideal for demanding environmental conditions like semiconductor manufacturing. P-BN crucibles are commonly used for smelting metals and semiconductors, with a usage temperature in a vacuum reaching as high as 1800 degrees.

4. Zirconia Crucible

Zirconia has a higher melting point than zirconium and is one of the most refractory materials in nature. Even if heated to 1900 ℃, zirconium oxide also won't react with the molten aluminum, iron, nickel and platinum metals, silicate and acid slag, etc., so the zirconia crucible can successfully smelt platinum, palladium, ruthenium, and cesium precious metals and their alloys.

Compared with alumina, zirconia is more expensive. Still, it is a special oxide refractory material that can be used in the high-temperature furnace above 2000 ℃, which is something that no other oxide can replace.

5. Yttrium Oxide Crucible

Yttrium oxide (Y2O3) ceramics are high-performance with excellent heat resistance, corrosion resistance, and high-temperature stability. The melting point of yttrium oxide is greater than 2400 ℃, and it is difficult to react with some active metals (such as Ti, Al, Hf, Nb, etc.) at high temperatures. The crucible, mainly composed of high-purity Y2O3, has the potential for melting Ti and Ti alloys, or any oxygen-sensitive melting process.

However, Y2O3 is difficult to process because of its high melting point. Since Y2O3 itself is very brittle, the crucible may rupture if the heating or cooling rate is too fast.

6. Silicon Carbide Crucible

Silicon carbide crucibles, renowned for their exceptional thermal conductivity and resistance to chemical corrosion, find their forte in high-temperature applications. Composed of silicon carbide, a compound of silicon and carbon, these crucibles excel in melting and refining metals like aluminum, copper, and iron. With the ability to withstand extreme temperatures, silicon carbide crucibles are favored in foundries and laboratories for various metallurgical processes.

![]()

7. Magnesia Crucible

Magnesia crucibles, crafted from magnesia or magnesium oxide, exhibit resistance to chemical corrosion and high-temperature stability. These crucibles find applications in laboratories and metallurgical processes, offering a reliable container for the melting and heating of metals.

8. Mullite Crucible

Mullite crucibles, composed primarily of alumina and silica, showcase the advantageous properties of both materials. With a low coefficient of thermal expansion, exceptional thermal shock resistance, and high mechanical strength, mullite crucibles find applications in various high-temperature processes. Their versatility makes them suitable for tasks ranging from metal melting to the synthesis of advanced materials.

9. Cordierite Crucible

Cordierite crucibles, featuring a composition of magnesium, aluminum, and silicon, offer a unique combination of thermal shock resistance and low thermal expansion. Often employed in applications requiring rapid heating and cooling cycles, cordierite crucibles find utility in laboratories and industrial settings. Their ability to withstand abrupt temperature changes makes them ideal for processes demanding precise control over thermal conditions.

10. Sintered Silicon Nitride Crucibles

Sintered silicon nitride crucibles stand out as advanced ceramic vessels designed for extreme conditions. Composed of silicon and nitrogen, these crucibles exhibit remarkable thermal stability, high strength, and resistance to chemical corrosion.

Sintered silicon nitride crucibles are commonly used in labs and industries for experiments or processes in harsh thermal and chemical conditions. They play a crucial role in advancing materials research and manufacturing technologies. Their exceptional properties make them a preferred choice for applications demanding stringent performance standards.

Conclusion

In conclusion, the diverse range of crucibles underscores their indispensable role in facilitating a spectrum of chemical processes. From traditional materials like quartz to advanced compositions like sintered silicon nitride, each crucible type serves a unique purpose, contributing to the efficiency and precision of various applications. As technology continues to advance, crucibles will likely evolve further, catering to increasingly specialized and demanding industrial and laboratory needs.