What is the Spherical Boron Nitride?

What is the spherical boron nitride? What is the hexagonal boron nitride? What are the differences between the spherical boron nitride and the hexagonal boron nitride? If you are looking for answers to those questions, then you've come to the right place. In this article, we will take a close look at the spherical boron nitride and the hexagonal boron nitride.

What Is the Spherical Boron Nitride?

Hexagonal boron nitride (H-BN) is a covalently bonded crystal composed of nitrogen and boron atoms, and it is known as "White Graphene" due to its graphite-like layered structure and its loose, lubricating, moisture-absorbent, lightweight appearance. The commercial products of hexagonal boron nitride have much morphology after modification, such as sheet boron nitride, boron nitride aggregates, boron nitride nano-sheet, boron nitride, and spherical boron nitride.

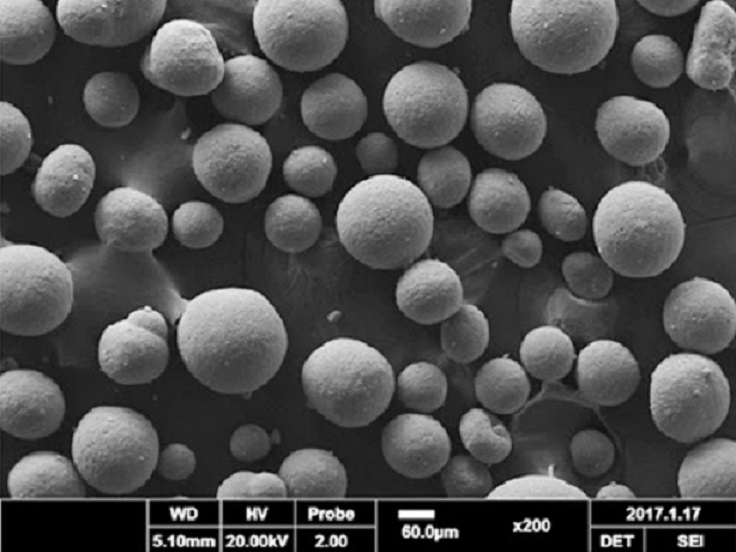

Among them, the spherical boron nitride is a polycrystalline sphere composed of boron nitride micron class single chip. Compared with the sheet, tube, and layer boron nitride, spherical boron nitride not only maintains the original excellent performance of boron nitride, such as less ionic impurities, low expansion coefficient, high dielectric strength, but also has the excellent quality of particle fluidity and high specific surface area.

The properties and key application fields of spherical boron nitride materials are as follows:

-

Composite Material "High Thermal Conductivity Filler"

Boron nitride has high thermal conductivity and is a hot candidate thermal conductive filler for rubber plastic composites. However, the boron nitride filler currently used is mostly flaky. Due to its irregular shape, the thermal conductivity in the direction of vertical crystal surface is far less than that in the direction of parallel crystal surface, resulting in that some chip orientation of boron nitride is perpendicular to the ideal thermal conductivity direction when it is highly filled into the polymer, which makes it impossible to make full use of the thermal conductivity of boron nitride.

Compared with sheet materials, the isotropy and specific surface area of spherical boron nitride are high, which can make up for the disadvantages of the orientation of boron nitride in the polymer that affects thermal conductivity and small filling amount, and meet the requirements of the high filling amount and high heat conductivity.

-

Lubricant Additives

At present, the lubrication life and load capacity of the lubricant additives used in the world are short. Hexagonal boron nitride has good lubrication property, especially high-temperature lubrication. Boron nitride has been used in commercial applications, such as the boron nitride ceramic engine protectant produced by the famous German lube brand. The spherical boron nitride nanoparticles retain the good properties of boron nitride and have higher wear resistance compared with other morphologies. As a lubricant additive, it is expected to have a better wear reduction effect.

-

Release Agent

Boron nitride has better high-temperature stability and good lubrication performance compared with traditional demolding agents such as graphite and carbon black. In the commercial application, sheet boron nitride has been applied in the demolding field. The spherical boron nitride has the characteristics of solid mass and isotropy, so its application in die casting, metallurgy, and glass mold stripper can improve the efficiency of the die and extend the service life of the die.

-

Refractory Coating

When the temperature is 900 ℃, the boron nitride oxidizes on the oxidizing atmosphere, and its maximum safe-use temperature in a vacuum can reach 2000 ℃, so it can be applied to the field of refractories. Boron nitride coating was prepared with boron nitride granules between 20 and 50 microns, and its performance can be improved by being attached to refractory materials or permeated into the refractory working layer. Spherical boron nitride is more stable and dispersed in solution due to its isotropic characteristics.

-

Adsorbing Materials

The spherical boron nitride with a high specific surface also has potential application value in the adsorption of organic pollutants. The spherical boron nitride was synthesized by the hydrothermal method under the control of the template. After that, the template in the precursor was removed by calcining, and then cracked at high temperature under the protective gas. Then, the spherical boron nitride was prepared by soaking. The spherical boron nitride has a large surface area, high porosity, high adsorption capacity for organic pollutants, and can be reused. It has a broad application prospect in water treatment, purification, and cleaning energy sources.

-

Carrier Materials

Boron nitride is resistant to high temperature and is chemically inert. It meets the requirements of stable catalyst carrier materials under a high-temperature oxidation atmosphere and does not react with the catalyst, which is more conducive to obtaining higher catalytic efficiency. The data is shown in the figure below.

-

Other Applications

In the field of biological medicine, the spherical boron nitride can also be used as the carrier for loading and sustained-release drugs. For example, the hollow spherical boron nitride has a large cavity volume, which can be used to store release genes and biological molecules.

The properties of different sizes of boron nitride are different, and the application areas are different, which are affected by such factors as particle size, purity, and impurity. For example, spherical boron nitride with particle sizes of 10-20 microns is usually used for refractory surface coating, while spherical boron nitride with particle sizes of 50-100 microns is mainly used for lubrication, demolding, insulation, and heat-conducting materials added in high-temperature environments, while those with sizes over 100 microns are mainly used for hot-pressed boron nitride raw materials. For all kinds of uses, boron nitride can also be classified according to ceramic grade, thermal conductivity grade, and lubrication grade.

In summary, spherical boron nitride has the dual advantages of original boron nitride and spherical morphology and overcomes the defects of lamellar boron nitride anisotropy and the large difference in thermal conductivity between vertical and horizontal surfaces. Compared with conventional boron nitride, spherical boron nitride has a wider application area and better product performance. It is believed that spherical boron nitride will play a more and more important role in organic/inorganic composites with further research on the forming mechanism and preparation technology of boron nitride.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the spherical boron nitride and the hexagonal boron nitride. If you want to learn more about boron nitride, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

As a leading supplier of boron nitride across the world, SAM enjoys over two decades of experience in the manufacture and sale of boron nitride, offering customers high-quality boron nitride products to meet their R&D and production needs. As such, we are confident that SAM will be your favorite boron nitride supplier and business partner.