Why is Cubic Boron Nitride Called a Superhard Material?

Why is cubic boron nitride called a superhard material? If you are looking for the answer to this question, then you've come to the right place. In this article, we will take a closer look at the cubic boron nitride and try to answer why cubic boron nitride is called a superhard material.

Why Is Cubic Boron Nitride Called a Superhard Material?

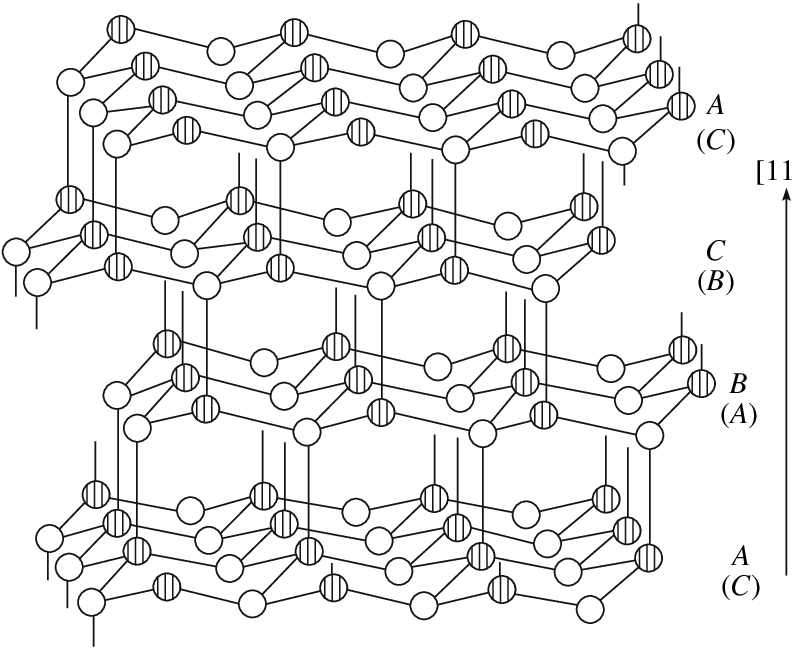

Cubic boron nitride (CBN) is a super hard material synthesized by hexagonal boron nitride and catalyst under high temperature and pressure. The hardness of this superhard material is second only to diamond in industrial application. The thermal stability of cubic boron nitride is much higher than that of diamond, and it has greater chemical stability for iron series metal elements. Therefore, the cubic boron nitride grinding tool has been widely used in the cutting and grinding fields of iron fund products with excellent performance.

There are two kinds of cubic boron nitride: single crystal and polycrystalline sintered body. The single crystal is obtained by controlling the hexagonal boron nitride and catalyst in pressure in 3000 ~ 8000 Mpa and the temperature in 800 ~ 1900 ℃. Typical catalyst materials are selected from alkali metals, alkali earth metals, tin, lead, antimony, and their nitrides. The crystalline form of cubic boron nitride has the truncated cone of tetrahedron, octahedron, skew crystal and twin crystal, etc. Commercially produced cubic boron nitride is black, amber, and gold-plated with particles usually less than 1 mm in size.

Application of Boron Nitride Polycrystal in Metal Cutting Field

Cubic boron nitride polycrystalline (PCBN) tool is a kind of superhard material product that is formed by the coalescence of many fine grains (0.1~100 micron) CBN. In addition to high hardness and abrasion resistance, it also has the characteristics of high toughness, chemical inertness, red hardness, etc., and can be polished with the cutting edge of the diamond grinding wheel. It shows excellent cutting performance in all aspects of machining and can achieve stable cutting at high temperatures, so it is especially suitable for machining all kinds of hardened steel, tool steel, chilled cast iron, and other hard-working materials with high hardness.

PCBN has most of the properties of CBN, and overcomes the disadvantages of directional cleavage of CBN single crystal surface, and has many performance advantages.

Application of Cubic Boron Nitride in Grinding Field

Cubic boron nitride has excellent grinding performance. It can not only complete the processing of difficult grinding materials, improve productivity, effectively improve the quality of the workpiece grinding, but also can strictly control the shape and size of the workpiece, as well as improve the surface integrity of the workpiece after grinding. Therefore, the fatigue strength of parts is improved and the service life is prolonged.

Cubic boron nitride powder is suitable for resin, metal, ceramic, and other binder systems, but also can be used for the production of polycrystalline composite, and even can be used as loose grinding particles, and grinding paste. As abrasive material, cubic boron nitride has long service life and good wear resistance. However, monocrystalline cubic boron nitride also has defects such as small grain size, anisotropy, and cleavage surface which is easy to be split.

Cubic boron nitride has many performance advantages, and its production process is less energy consumption and less environmental pollution than other superhard materials. Therefore, the use of cubic boron nitride is a major contribution to metal grinding, leading to a revolutionary change in grinding, which can be said to be the second leap in grinding technology.

Conclusion

Thank you for reading our article and we hope it can help you know why is cubic boron nitride called a superhard material. If you want to learn more about boron nitride, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

As a leading supplier of boron nitride across the world, SAM enjoys over two decades of experience in the manufacture and sale of boron nitride, offering customers high-quality boron nitride products to meet their R&D and production needs. As such, we are confident that SAM will be your favorite boron nitride supplier and business partner.