Discovery, Properties, and Applications of Molybdenum

Molybdenum is a silver-white metal, hard and tough, with a high melting point and high thermal conductivity. It does not oxidize with air at room temperature. Because molybdenum has the advantages of high strength, high melting point, corrosion resistance, and wear resistance, it is widely used in steel, petroleum, chemical, electrical and electronic technology, medicine, and agriculture. In this article, let's take a closer look at the discovery, properties, and applications of molybdenum.

Discovery, Properties, and Applications of Molybdenum

The Discovery of Molybdenum

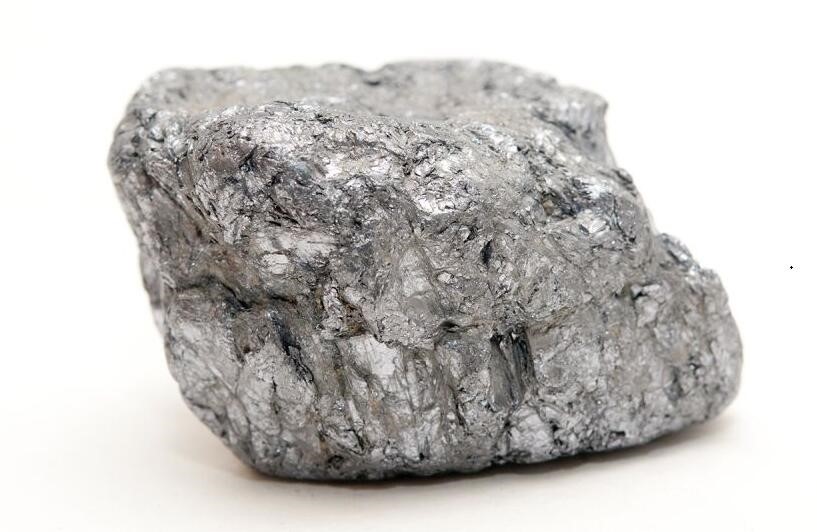

Molybdenum is a hard silver-white metal. So how was molybdenum discovered?

The soft black mineral molybdenite (molybdenum sulfide) was often mistaken for graphite or lead ore until 1778 when an analysis by German chemist Carl Scheele revealed it was neither one of these substances and was in fact, a totally new element. But since Scheele did not have a suitable furnace to reduce the white solid to metal, it would still be a few years before the element was actually identified, according to Chemicool.

In fact, Scheele later became known as "hard-luck Scheele" because he made a number of chemical discoveries — including oxygen — but the credit was always given to someone else. For the next few years, scientists continued to assume that molybdenite contained a new element, but it still proved very difficult to identify, since no one had been able to reduce it to metal. Some researchers did convert it to oxide, however, upon which when added to water, formed molybdic acid, but the metal itself remained elusive.

Eventually, Swedish chemist Peter Jacob Hjelm ground molybdic acid with carbon in linseed oil to form a paste. The paste allowed for close contact between the carbon and the molybdenite. Hjelm then heated the mixture in a closed crucible to produce the metal, which he then named molybdenum, after the Greek word "molybdos," meaning lead. The new element was announced in the autumn of 1781, according to the Royal Society of Chemistry.

Development of Molybdenum Industry

In 1891, France's Snyder Schneider took the lead as molybdenum alloying element to produce molybdenum armor plate, then he found the performance of molybdenum is superior to that of tungsten, so molybdenum gradually replaced the tungsten to become alloy elements of steel, which is the beginning of the industrial application of molybdenum.

In 1900, the ferromolybdenum production process has been developed, so molybdenum steel can meet the special performance need of gun steel also been discovered, which makes the production of molybdenum steel has been developed rapidly in 1910. Since then, molybdenum has become an important component of heat-resistant and anti-corrosion structural steels and has also become an important component of nonferrous metals nickel and chromium alloys.

The metal molybdenum is widely used in the electrical industry. One of the reasons is that the production of powder metallurgy and pressure processing technology of these two kinds of dense metal has been studied successfully, which can be used in production.

Another reason is that the outbreak of the First World War led to a surge in demand for tungsten, and molybdenum supply shortage has accelerated as much high hardness and impact resistance of tungsten steel substitutes. With the growth of demand for molybdenum, people began to search for new sources of molybdenum, and finally, a large Clay Max molybdenum deposit was discovered in Colorado, USA, and began to be mined in 1918.

To address the sharp decline in demand for molybdenum after World War I, people began to study the application of molybdenum in new civilian industries, such as the use of alloy steels containing molybdenum for the production of wheels. In 1930, researchers have proposed the forging and heat treatment of molybdenum-based high-speed steel must have the appropriate degree, this discovery opens the new application market for molybdenum, as alloying elements have also entered a new stage of molybdenum in steel and other fields.

By the end of the 1930s, molybdenum had become a widely used industrial raw material. During World War II, the American Clay Max molybdenum company developed a vacuum arc smelting process, in which 450-1000 kilograms of molybdenum ingots were obtained, which opened the way for molybdenum as a structural material.

Applications of Molybdenum in Modern Industries

Molybdenum is mainly used in the steel industry (80%), followed by its applications in the chemical field, which roughly accounts for 10%. In addition, molybdenum is also used in electrical and electronic technology, medicine and agriculture, and other fields.

- Steel Industry

In the steel field, molybdenum is mainly used for the production of alloy steel, stainless steel, tool steel, high-speed steel, cast iron, and roll. The use of molybdenum as the additive can enhance the strength and toughness, corrosion-resistance, and wear-resistance of steel, improve the hardenability, weldability, and heat-resistance of steel. The formation of molybdenum alloy by adding other elements to molybdenum, such as molybdenum lanthanum alloy and TZM alloy, has a better performance than pure molybdenum.

- Chemical Industry

Molybdenum can be used as lubricants, catalysts, pigments, flame retardants and smoke suppressants, and corrosion inhibitors of an organic polymer in the chemical field. The main products include molybdenum dioxide, molybdenum yellow, molybdate, ammonium paramolybdate.

- Electronic and Electrical Industry

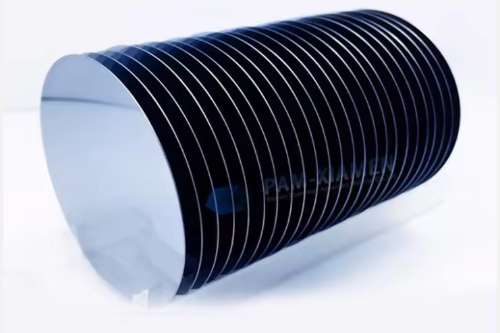

Molybdenum has good electrical conductivity and high-temperature resistance. Its thermal expansion coefficient is similar to that of glass. It’s widely used in the production of the core wire, lead wire, hook, and other components of the spiral filament. Molybdenum wire is also the ideal electrode wire for a cutting tool machine, which can cut a variety of steel and carbide. Its processing is stable, which can effectively improve the precision of the mold.

- Medical Field

Molybdenum is an essential nutrient. Molybdenum is an essential mineral in the body, just like iron and magnesium. It is present in soil and transferred into your diet when you consume plants, as well as animals that feed on those plants.

Molybdenum is vital for many processes in your body. Once you eat it, it is absorbed into your blood from your stomach and gut, and then carried to your liver, kidneys, and other areas. Some of this mineral is stored in the liver and kidneys, but most of it is converted into a molybdenum cofactor. Any excess molybdenum is then passed in the urine. The molybdenum cofactor activates four essential enzymes, which are biological molecules that drive chemical reactions in the body.

- Animal Husbandry and Agricultural Field

In animal bodies, molybdenum is a molybdenum enzyme composition, and adding the molybdenum additives to the feed can achieve the goal of meeting the needs of animals. Besides, molybdenum is also one of the essential trace elements for plant growth. Seeding using ammonium molybdenum can greatly increase the yield of flowers.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the discovery, properties, and applications of molybdenum. If you want to learn more about molybdenum and molybdenum alloys, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

As a leading supplier of molybdenum products across the world, SAM enjoys over two decades of experience in the manufacture and sale of molybdenum tube, molybdenum powder, and molybdenum alloys, offering customers high-quality molybdenum products to meet their R&D and production needs. As such, we are confident that SAM will be your favorite molybdenum product supplier and business partner.