Types, Properties & Applications of Tantalum Powder

If you are browsing our website and reading this article, then you may be interested in tantalum metal and tantalum powder. But you may not be quite familiar with the types, properties & applications of tantalum powder, so in this article, we will introduce how many types of tantalum powder out there and what are their properties and applications. Before diving into our article, let's figure out what's tantalum powder first.

Types, Properties & Applications of Tantalum Powder

What is tantalum powder?

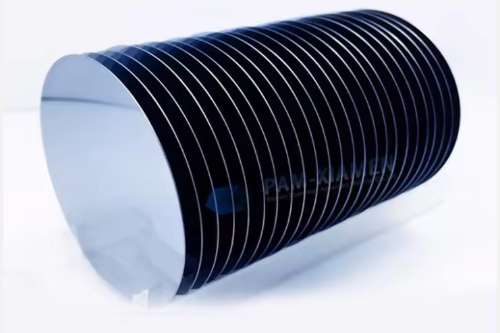

Tantalum powder is powdered metallic tantalum, which is dark gray or silver-gray. It is an important raw material for the preparation of capacitors and tantalum materials.

How many types of tantalum powder out there?

According to its use, tantalum powder can generally be divided into capacitor grade tantalum powder and metallurgical grade tantalum powder.

Properties & Applications of Capacitor Grade Tantalum Powder

Capacitor-grade tantalum powder is generally divided into three series: low-voltage series (working voltage not greater than 25V), medium-voltage series (working voltage is 32-40V), and high-voltage series (working voltage is not less than 50V).

Capacitor-grade tantalum powder is used to manufacture tantalum capacitor cores. Its quality is mainly determined by its physical properties, chemical composition, and electrical properties.

(1) Physical properties. The physical properties mainly include average particle size, particle shape, fluidity, and forming density. Low-voltage series products should have a small average particle size, complex particle shape, and low forming density, while high-voltage series products should have a larger average particle size, simple particle shape, and higher forming density.

The fluidity determines whether the tantalum powder can be formed by an automatic forming machine. Therefore, with the rapid increase in the production of small chip tantalum capacitors, people have paid great attention to the fluidity of tantalum powder.

(2) Chemical composition. The chemical composition has a direct effect on the electrical properties of tantalum powder. High impurity content, especially high phosphorus, boron, oxygen, carbon, potassium, sodium, and iron content, will increase the leakage current and decrease the breakdown voltage of the tantalum anodic oxide film, thereby deteriorating the electrical properties of the tantalum powder.

However, the content of certain elements in tantalum powder is not as low as possible. It was found that the incorporation of certain selected elements can improve certain electrical properties of tantalum powder. The practice has proved that adding a small amount of phosphide to the tantalum powder can inhibit the shrinkage of the tantalum block during sintering, thereby increasing the weight-specific capacitance of the tantalum powder, and incorporating a small amount of aluminide with high dielectric strength can increase the breakdown voltage of tantalum powder.

(3) Electrical properties. Electrical properties refer to the DC leakage current, breakdown voltage, and capacitance of the tantalum anode block after the tantalum powder is weighed, compacted, vacuum sintered, and anodized. All these properties are not only determined by the intrinsic properties of the amorphous tantalum pentoxide anodic oxide film but also closely related to the physical properties and chemical composition of the tantalum powder.

Properties & Applications of Metallurgical Grade Tantalum Powder

Metallurgical grade tantalum powder is used to prepare various tantalum materials or tantalum powder as alloy additives, so its quality is mainly measured by its physical properties and chemical composition. The particle size as an important physical performance index is better to pass a 150-mesh standard sieve and the bulk density is preferably 3-6g/cm3. In order to avoid the loss of chemical composition during vacuum sintering and melting, the oxygen content should be controlled at about 0.2%. Since tungsten, molybdenum, niobium, and other high melting point metals cannot be removed in the vacuum melting process, their content should be strictly controlled.

The Preparation Methods of Tantalum Powder

The methods of preparing tantalum powder include metal thermal reduction of tantalum pentoxide, carbon reduction, molten salt electrolysis, hydrogen reduction of tantalum halide, metal thermal reduction, and metal thermal reduction of tantalum-containing fluorine complex, etc.

At present, the industry mainly uses the sodium reduction method of potassium fluorotantalate to prepare metal tantalum powder, and the reaction formula is K2TaF7+5Na=Ta+2KF+5NaF.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the types, properties & applications of tantalum powder. If you want to know more about tantalum and tantalum powder, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.