SAM Launches Polymer Tungsten for Radiation Shielding

Stanford Advanced Materials (SAM), the industry leader in materials, is proud to announce the release of its new polymer tungsten for radiation shielding. This is a remarkable achievement in the move towards environmentally friendly solutions for radiation shielding.

Polymer Tungsten for Radiation Shielding

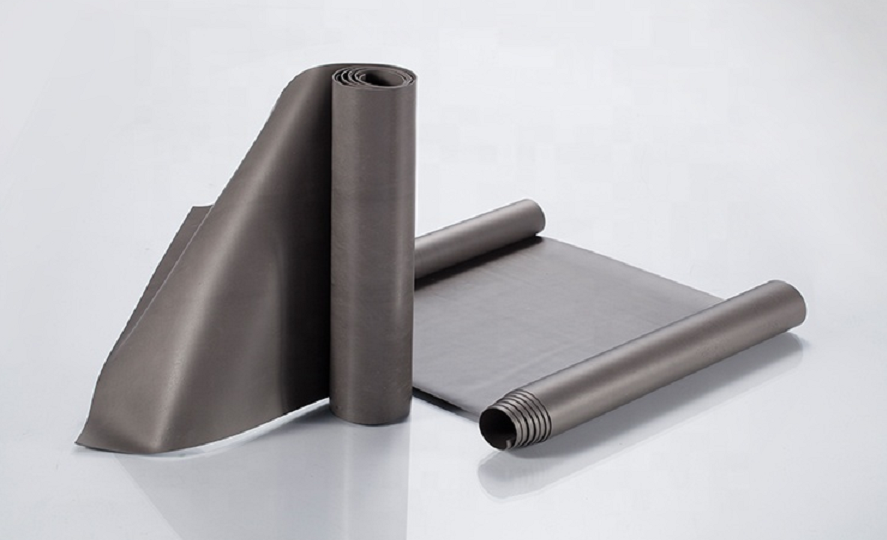

Rita from SAM explains, “Tungsten is an excellent radiation material, but it’s too fragile to be curved into desired shapes. However, when you put tungsten powder with polymer to make a polymer tungsten composition, you get a flexible radiation-resistant material. SAM is continuously striving to find innovative solutions to meet customer needs. Given the environmental costs of lead, poly tungsten will surely replace it in the coming years.”

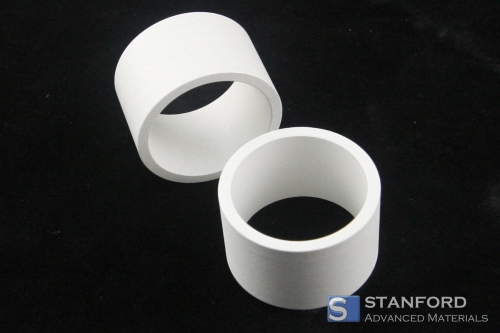

Polymer Tungsten (also known as Tungsten-filled Polymer and PolyTungsten) is a composition of various resins and Tungsten powder which are mixed together through special metallurgical technology. Compared with other materials, tungsten poly has its own properties; it can be easily machined, has high radiation resistance, and is environmentally friendly. Traditionally, lead (Pb) was the best option for shielding against radiation. It is inexpensive and abundant, but it is toxic and highly hazardous. In fact, it is ranked number two on the United States’ “Priority List of Hazardous Substances”.

PolyTungsten has the same density and thickness as lead, therefore providing equivalent shielding properties. In addition, it is the leading substitute as it is more durable and better for the environment. It is nontoxic, dependable, and meets US, EPA, OSHA, and RoHS standards. Furthermore, it keeps its form during use and can be used in many applications, such as X-ray equipment, CT scanning devices, tungsten poly syringe, and tungsten poly collimator, to name a few. Analysis, both on samples and actual products already in use, has confirmed that SAM’s tungsten-filled polymer products offer radiation shielding superior to lead material radiation shielding without leakage or hot spots.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the polymer tungsten for radiation shielding. If you want to learn more about polymer tungsten or other tungsten products, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

Stanford Advanced Materials (SAM) is a worldwide supplier of tungsten products and has over two decades of experience in the manufacture and sale of tungsten and tungsten alloys, providing high-quality tungsten products to meet our customers' R&D and production needs. As such, we are confident that SAM will be your favorite tungsten product supplier and business partner.