Corrosion resistance of tantalum to water, aqueous solutions and non-metals

Tantalum - Element information, properties

Tantalum is a sensible choice whenever high corrosion resistance is required. Tantalum is often compared to precious metals because it is resistant to all types of chemical substances. However, in thermodynamic terms, tantalum is a base metal that can nevertheless form stable compounds with a wide variety of elements. When exposed to air, tantalum forms a very dense oxide layer (Ta2O5) which protects the base material from aggression. This oxide layer, therefore, makes tantalum corrosion-resistant.

Tantalum VS Hydrogen

Tantalum (Ta) metal has a high melting point (i.e., 3017 °C), high corrosion resistance, and high room-temperature ductility. Pure Ta in both welded and un-welded conditions has very low ductile-to-brittle transition temperatures (i.e., less than − 269 °C).

Tantalum is the most corrosion-resistant metal in common use today. The presence of a naturally occurring oxide film on the surface of tantalum is the reason for tantalum's extreme corrosion-resistant properties in aggressive media. Its corrosion resistance in sulfuric acid and hydrochloric acid is second to none. It is inert to practically all organic and inorganic compounds. Tantalum's corrosion resistance is very similar to that of glass, as both are unsuitable for use in hydrofluoric acid and strong hot alkali applications.

Tantalum is inert to sulfuric and hydrochloric acid in all concentrations below 150°C. The corrosion attack on tantalum is insignificant up to 205°C and tantalum has been in use up to 260°C.

Tantalum is not corroded by nitric acid in concentrations up to 98% and temperatures up to at least 100°C and has proven itself to be totally inert in many corrosion applications.

The material is resistant to aqueous ammonia solutions. If tantalum is exposed to chemical aggression, hydrogen enters its metal lattice and the material becomes brittle. The corrosion resistance of tantalum falls gradually with increasing temperature.

Tantalum is inert in contact with many solutions. However, if tantalum is exposed to mixed solutions, its corrosion resistance may be impaired even if it is resistant to the individual components taken separately.

|

Corrosion resistance to water, aqueous solutions, and non-metals |

||

|

Water |

Hot water < 150 °C |

resistant |

|

Inorganic acids |

Hydrochloric acid < 30 % up to 190 °C |

resistant |

|

Organic acids |

Acetic acid < 100 % up to 150 °C |

resistant |

|

Lyes |

Sodium hydroxide < 5 % up to 100 °C |

resistant |

|

Saline solutions |

Ammonium chloride < 150 °C |

resistant |

|

Non-metals |

Fluorine |

not resistant |

Feel free to contact us: molly@samaterials.com

Conclusion

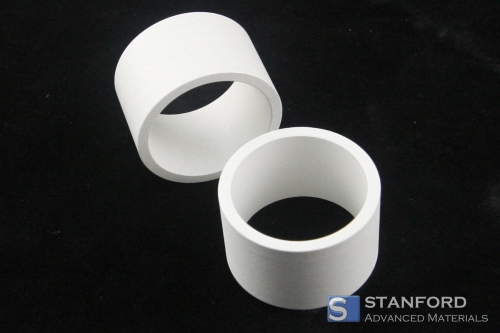

Thank you for reading our article we hope it can help you learn how to improve the properties of tantalum well. If you want to know more about tantalum and other refractory metals and alloys, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

Stanford Advanced Materials (SAM) is a worldwide supplier of tantalum products and has over two decades of experience in the manufacture and sale of tantalum products, offering high-quality tantalum metals to meet customers' R&D and production needs. As such, we are confident that SAM will be your favorite tantalum supplier and business partner.