Introduction to Tungsten and Tungsten Crucibles

1. What is Tungsten?

Tungsten is a metal that is also known as wolfram and is extracted from its ores - wolframite, and scheelite. This element was identified as a new element in 1781 and as an isolated element in the year 1783. This is a rare and hard chemical element that has the highest melting point, high tensile strength, high density, and low vapor pressure. Tungsten’s atomic number is 74 and is denoted as a symbol W. The word tungsten comes from a Swedish word -Tung Sten, which means heavy stone.

2. Occurrence of tungsten

Tungsten metal is found to be naturally occurring in minerals wolframite, ferberite, scheelite, and hubrenite. At present, China is the largest tungsten producer while most of the remaining production comes from Russia, Canada, and Bolivia.

To obtain tungsten from its ores, tungsten ores are crushed, cleaned, and treated with alkalis for obtaining tungsten trioxide. After this, tungsten trioxide is heated with carbon or hydrogen gas to obtain the tungsten metal and carbon dioxide or water vapor and tungsten metal.

3. Major applications of tungsten

A. Alloys

Due to extreme hardness and density, tungsten is often used to obtain hard metal alloys. Its high melting point makes it a good material for making rocket nozzles, turbine blades wear-resistant parts, etc. The alloys of tungsten are used in the automotive industry and the aerospace industry as well.

B. Tungsten carbides

Tungsten carbides (formula WC) are vital tungsten products because they belong to cemented carbides also known as hard metals and are widespread in today’s high-tech tools.

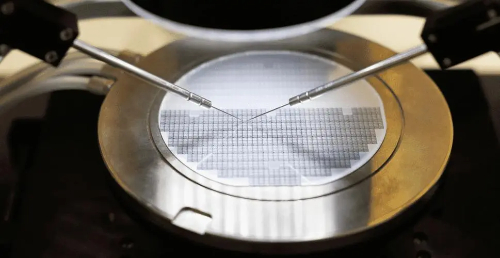

C. Electronics

Tungsten is used in making many electronic types of equipment such as light bulbs, cathode ray tubes, vacuum tube filaments, heating elements, electronic contacts, etc. Some other equipment that can be made using tungsten are field emission guns, electron microscopes, transistors, etc.

D. Gold substitution

Since the density of tungsten is very high and is quite similar to that of gold, it can be used as a gold substitute and is used for making jewelry, etc. It is used for making resist which is resistant to scratching and counterfeiting of gold bars, etc.

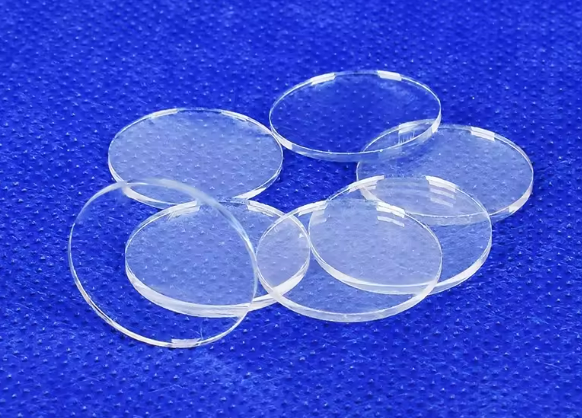

4. Introduction to tungsten crucible

Tungsten crucibles are vessels made of tungsten or tungsten alloys and are used for melting and calcining materials at high temperatures. Tungsten crucibles are increasingly being used for a variety of purposes and are being produced by many companies. These are made in a variety of designs, and shapes, depending upon the specifications of the clients. Tungsten crucibles are often prepared in addition to molybdenum of up to 0.9% or some other elements in slight quantities. The following are some major usages of tungsten crucibles:

• These crucibles are mainly used for growing sapphires and monocrystals. They are also used for rare earth metal melting.

• Due to the resistance to certain metal oxides and molten metals, tungsten crucibles are used in electronic product making, technologies for thermal vaporization, etc.

• It is also used in heating elements for induction furnaces, smelting of metals, making high-temperature containers, etc.