Military Tungsten Alloy Counterweight

The military tungsten alloy counterweight has high density, high hardness, high tensile strength, wear resistance, impact resistance, high-temperature resistance, corrosion resistance, easy processing, radiation resistance, and good creep resistance. It is also environmentally friendly and non-toxic.

Military Tungsten Alloy Counterweight

Compared with many similar counterweight products, the advantage of military tungsten alloy counterweight lies in its high mass/size ratio, that is, a larger specific gravity can be achieved in a smaller volume, so it is especially suitable for applications with limited space. For example, it can be used as a core filling material for armor-piercing projectiles, or as a counterweight for heavy weapons, thereby reducing recoil.

Advantages of Military Tungsten Alloy Counterweight

1. High Density

Tungsten alloy counterweight is made of high specific gravity tungsten alloy, so the density is very high (16.5-19cm³), which can reach more than twice the density of ordinary steel.

2. Good Machining Characteristics

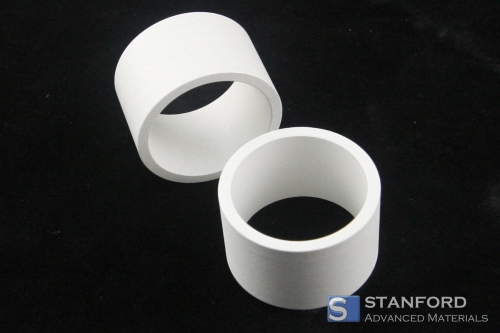

Because tungsten alloy counterweights have good ductility, they can be machined, milled, planed, threaded, and tapped. In addition, tungsten alloy counterweights can also be subjected to large deformation strengthening treatments such as swaging and forging processing, to manufacture parts of various shapes.

3. Good Ductility

The bulk product made of W-Ni-Fe high-density alloy has good ductility, and its elongation in the sintered state can reach 10%-15%. After vacuum or atmosphere dehydrogenation treatment, the elongation can be increased to 20%-30%.

4. High Tensile Strength

The tensile strength of the sintered arc-shaped tungsten alloy counterweight is 800-1000MPa, and its strength can be increased to 1300-1500MPa after heat treatment and deformation processing.

5. Good Thermal Conductivity and Low Linear Expansion Coefficient

The thermal conductivity of tungsten alloy counterweight is 5 times that of die steel, and its linear expansion coefficient is only 1/2-1/3 of iron or steel.

Applications of Tungsten Alloy Counterweights

Tungsten alloy counterweights are widely used in various fields. In addition to military use, they can also be used for mechanical counterweights and flying hammers, weighting rods used in oil and other drilling industries, clock pendulums, shock-proof knife bars, counterweight balls, vibrators used in mobile phones and game consoles, ballast counterweights, and counterweight components for navigation and sailing, gyroscopes and aircraft counterweights used in aerospace, etc.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of military tungsten alloy counterweight. If you want to know more about tungsten and tungsten alloys, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

Stanford Advanced Materials (SAM) is a worldwide supplier of tungsten products and has over two decades of experience in the manufacture and sale of tungsten and tungsten alloys, providing high-quality tungsten products to meet our customers' R&D and production needs. As such, we are confident that SAM will be your favorite tungsten product supplier and business partner.