Zirconia Structures for Dentistry

Introduction

Zirconia structures have revolutionized modern dentistry, providing durability and precision in dental restorations. This article delves into the intricacies of fabricating zirconia structures using CAD-CAM technology, exploring the methods, advantages, and challenges of this innovative approach.

CAD-CAM Technology in Zirconia Fabrication

Utilizing Computer-Aided Design and Computer-Aided Manufacturing (CAD-CAM) technology, zirconia structures are crafted with unparalleled precision. Two primary methods are employed in this process, each presenting unique considerations.

Milling from Fully Sintered Blocks:

- Pros: Direct milling from fully sintered zirconia blocks eliminates structural shrinkage, delivering the final form without additional adjustments.

- Cons: Excessive wear on grinding tools and the introduction of flaws during machining may compromise mechanical reliability.

Milling from Pre-Sintered Blocks:

- Pros: Pre-sintered blocks allow adjustments for structural shrinkage during the designing stage, ensuring a precise fit after final sintering.

- Cons: Complexities associated with compensating for shrinkage require meticulous planning.

CAD-CAM Process Overview

The CAD-CAM process unfolds in three key steps:

- Digital Data Acquisition: Precise digital data capturing sets the foundation for accurate design and fabrication.

- Computer Processing and Designing: Advanced computer algorithms process the acquired data, facilitating the meticulous design of the zirconia structure.

- Fabrication: The designed structure is brought to life through milling or machining processes, resulting in a tailored zirconia restoration.

Esthetic Considerations and Advances

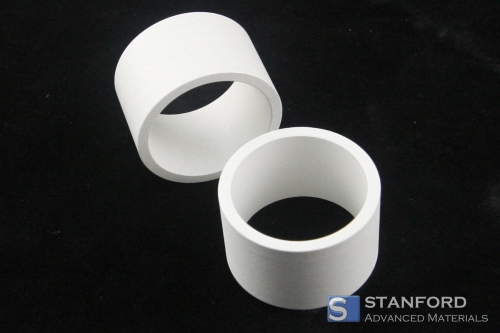

Traditionally possessing a dull white color, zirconia's opacity posed challenges in revealing the underlying structure. Modern dental zirconia systems address this by incorporating structural coloring and enhancing esthetics. Monolithic zirconia restorations, with anatomical shapes, minimize the need for extensive dental laboratory work.

Challenges and Future Investigations

Despite advancements, challenges persist. Yttria-stabilized tetragonal zirconia polycrystal (Y-TZP) faces stability issues in wet environments, with potential strength degradation due to crystallographic transformations and cyclic fatigue from para-functional habits. Ongoing research focuses on understanding low-temperature degradation (LTD) impacts on dental zirconia.

Veneering Techniques

The porcelain veneering of zirconia infrastructures plays a pivotal role in achieving anatomical contour and esthetic appeal. Two prominent veneering methods are employed:

Traditional Layering Technique:

- A meticulous layering approach, building up porcelain in stages to achieve desired esthetics.

Hot Pressing Method:

- A modern technique involves applying heat and pressure to create a seamless bond between zirconia and veneer.

Conclusion

Zirconia structures, harnessed through CAD-CAM technology, represent the pinnacle of precision in modern dentistry. Despite challenges, ongoing research and innovative veneering techniques ensure that zirconia remains a cornerstone in achieving durable, aesthetically pleasing dental restorations. At Stanford Advanced Materials, we embrace cutting-edge methodologies to contribute to the evolution of dental materials and technologies.