Direct Energy Disposition - 3D Printing Methods

Direct Energy Disposition (DED) is one of the additive manufacturing methods. Additive manufacturing (AM) may seem a little bit unfamiliar to you. It is also called 3D printing, rapid prototyping (RP), layer manufacturing, etc. The main core of addictive manufacturing is using 3D model data to join materials layer by layer. Without the need for tools or pre-producing dies, AM defeats traditional manufacturing technologies and has become one of the most popular producing methods nowadays. Since addictive manufacturing can use various materials, such as plastics, metals, ceramics, composites, and biological materials as its deposited materials [1], lots of industries have started to or have already used this technology. AM gives the possibility to make complicated and specific designs.

Additive manufacturing includes four methods: binder jetting, powder bed fusion, sheet lamination, and direct energy deposition (DED). As you can see from the title, we will focus on direct energy deposition in this article.

What is Direct Energy Deposition?

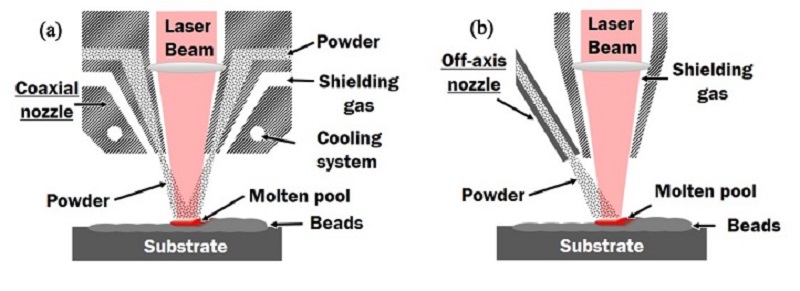

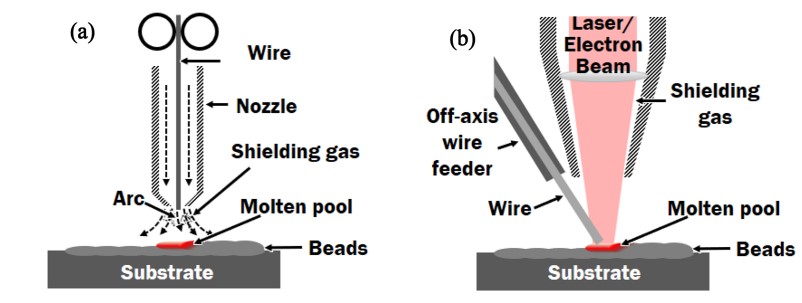

Direct Energy Deposition uses thermal energy provided by a laser/ electric beam or something else to melt the material and fuse the deposition with the new material. It combines cladding and welding technologies. DED not only uses powder, like other 4 AM methods but also uses wires as its feedstock. According to different feedstock types, DED can be divided into powder and wire feeding types. The powder-feeding type DED uses a laser as its thermal heat to melt the powder and previous layers. The wire-feeding type DED can use a laser, an electron beam, or a plasma arc as its thermal heat. Figure 1 and Figure 2 below can give you a brief understanding of these 2 different DED technologies.

Figure 1: Powder feeding type DED: (a) coaxial feeding; (b) off-axis feeding [1]

Figure 2: Wire feeding type DED: (a) coaxial feeding; (b) off-axis feeding [1]

According to different feeding locations, DED can be divided into coaxial and off-axis feedings. Shielding gas or protecting gas is used to protect the material especially active metal from oxidizing because of high temperature.

Its key working principle is as follows:

*The nozzle provides the feedstock (powder or wire) on the substrate

*A heating resource (such as a laser) melts the specific area and fuses the material to form a layer

The nozzle and laser beam move continuously to other areas to retake the same action controlled by the computer. Direct energy deposition uses the line-by-line principle and can work under the nonhorizontal plane.

Deference Between Powder Feeding and Wire Feeding Type DED

The wire-feeding type DED has a higher deposition rate and thicker layer than the powder-feeding type DED. However, the powder-feeding type DED is more accurate (elaborated) and has less residual stress. These differences make them often used in different applications.

The powder-feeding type DED is often used in restoration, porous coating, tailored materials, tailored structures, and thermal management [1]. Unlike powder bed fusion or binder jetting, DED can be used in restoration because it can work under the nonhorizontal working plane.

The wire-feeding type DED is often used in producing large-sized particles such as wing spars.

Application of Direct Energy Deposition Restoration

Direct energy deposition shows excellent performance in remanufacturing and restoration areas, especially when completely replacing a component is time-consuming and expensive. For example, when part of the integrally bladed rotor of modern turbine engines is damaged, it is less economical to replace it with a new blade than to repair it. It is not easy to use general technologies to achieve it. But DED can fix this problem with relatively low heat input, small distortion, good metallurgical combination, and accurate fitness.

The powder-type DED shows better performance than the wire-type DED in restoration. However, neither can restore the same fatigue properties, yield stress, and ductility as the original part due to porosity, impurities, or other reasons.

As DED technology continues to evolve, it is likely that the size and complexity of parts that can be produced using the process will also increase. This will open up new possibilities for manufacturers and restoration organizations, and could potentially lead to the development of entirely new products and industries.

Summary

Direct energy deposition is a highly precise and accurate addictive manufacturing process that has the potential to revolutionize the way we create and repair parts. While it is currently limited to the production of small parts, ongoing developments in the technology are likely to expand its capabilities in the future. The high cost of the equipment required to perform DED may be a barrier to adoption for some organizations, but the benefits of the process make it an increasingly popular choice for a wide range of applications.

Reference

- Ahn, DG. Directed Energy Deposition (DED) Process: State of the Art. Int. J. of Precis. Eng. and Manuf.-Green Tech. 8, 703–742 (2021). https://doi.org/10.1007/s40684-020-00302-7