Iridium: Civilian Hero in Precious Metals

Introduction:

Amidst reports of unscrupulous merchants utilizing iridium to adulterate gold, a clandestine practice that turns 20 grams of gold into 25 grams, iridium emerges as a silent hero in the realm of precious metals. Not only does it share elemental attributes with gold, but it also presents an economical alternative.

This article aims to unveil the nature of iridium, exploring its role in the precious metal family and the myriad applications that make it a versatile and valuable commodity.

In the Precious Metal Family:

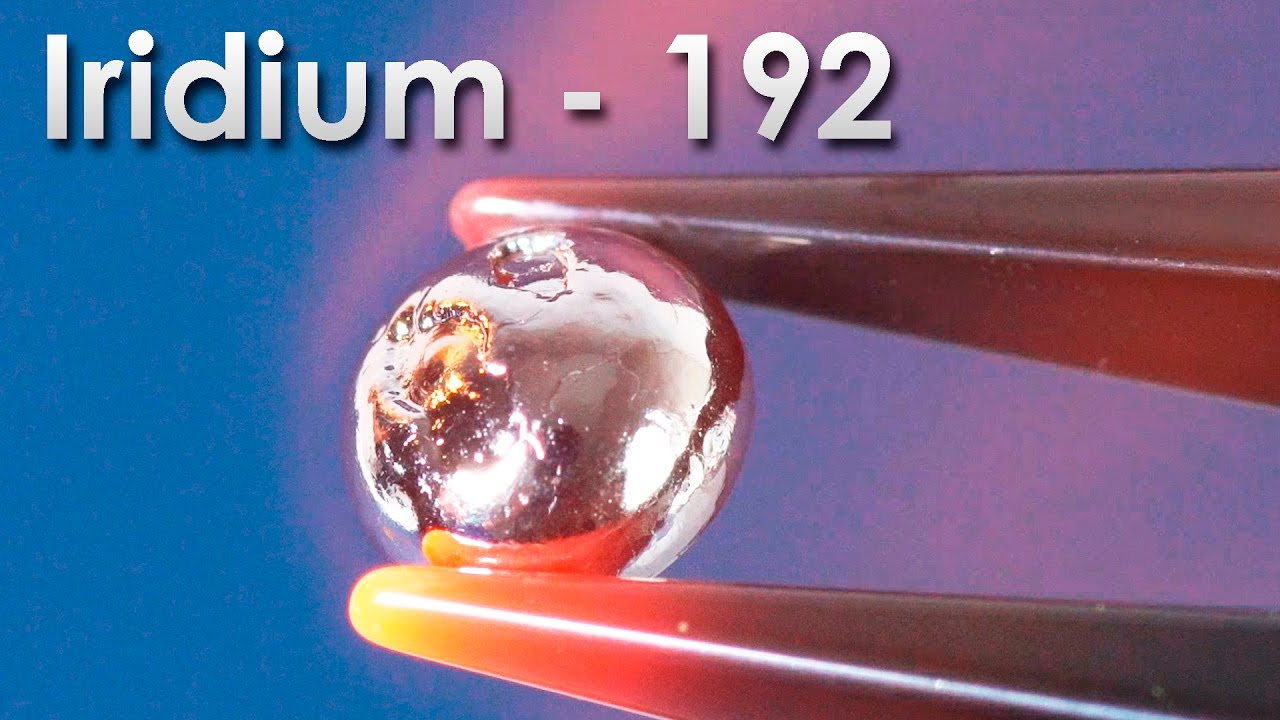

Iridium, with its atomic number 77 and atomic weight of 192.22 in the periodic table, stands as a distinguished member of the platinum metal group. Although it occurs at a mere one-millionth concentration and is scarce in the Earth's crust, it is often found intertwined with platinum elements in alluvial deposits and ore formations. This rarity contributes to the high value placed on iridium within the precious metal spectrum.

Recovery and Recycling:

Being part of the platinum group metals, it is subject to meticulous recycling efforts. Platinum is found in waste catalysts, broken utensils, and discarded electrical components. Lead, rhodium, osmium, and ruthenium are processed to make iridium powder through leaching, calcining, melting, distillation, and dissolution. This recycling not only ensures the efficient use of resources but also underscores the economic importance of iridium.

Multi-Functional Marvel:

Ir boasts a density of 22.65 grams per cubic centimeter, making it the densest among known elements. Its exceptional melting point of 2454 ℃ allows for applications in high-temperature environments ranging from 21 to 2200 ℃. At lower temperatures, iridium exhibits remarkable plasticity.

Notably, Ir stands out as the most corrosion-resistant metal, impervious to the effects of general caustic agents. Iridium cannot dissolve in mineral acids and is resistant to other metal melts. Like other platinum metal alloys, it is a catalyst that can absorb organic matter.

Applications Across Industries:

Owing to its high melting point and robust corrosion resistance, iridium finds widespread use across various industries. It has become a staple in aerospace, pharmaceutical, and automotive applications. Originally employed as a pen tip material, iridium's utility expanded to include injection needles, balance blades, compass supports, and electrical contacts.

In chemical laboratories, it plays a crucial role, in forming laboratory utensils such as crucibles, electrodes, and resistance wires from platinum-iridium alloys. The iridium crucible, for instance, is instrumental in growing refractory oxide crystals, enduring high-temperature conditions for thousands of hours.

Specialized Uses and Innovations:

Beyond conventional applications, iridium finds itself in specialized roles. It serves as a container for radioactive heat sources and demonstrates promise as a material for oxide films, contributing to advancements in color technology. Ir192, an isotope of Ir, emerges as a gamma-ray source employed in nondestructive testing and radiochemotherapy, showcasing the diverse and evolving applications of this precious metal.

Conclusion:

In conclusion, iridium stands as a civilian hero in the realm of precious metals, offering not only economic benefits in certain practices but also versatile applications across diverse industries. Its scarcity, coupled with remarkable properties such as high density, corrosion resistance, and adaptability to extreme temperatures, positions it as a valuable and sought-after commodity.

From its humble origins as a pen tip material to becoming an integral part of advanced technologies in aerospace and healthcare, iridium continues to play a crucial role in shaping the landscape of modern industry. As we delve deeper into the potential and applications of iridium, we uncover a fascinating tale of innovation and resourcefulness in the world of precious metals.