What You Should Know about Molybdenum Alloys

The word molybdenum comes from the Latin word "Molybdaenum", which means lead. The molybdenum mineral was found to be in existence since pre-historic times but was only isolated as a particular element by Peter Jacob Hjelm in 1781. Prior to being identified as a distinct element, it was often confused with graphite and lead ore. Blended with other elements to produce molybdenum alloys, moly has become an element that is high in demand for steel production and other applications.

1. Basic Information of Molybdenum

Molybdenum is a silvery, shiny metal that belongs to Group 6A, the second transition series of the Periodic Table. It has the 6th highest melting point and is the 54th most abundant element in the world. The highest molybdenum reserves of molybdenum ore can be found in the U.S., Canada, China, Peru, and Chile.

Because of its properties, it serves as a good thermal conductor and as an important alloying element in the production of structural and stainless steel. It has a high ability to resist corrosion and to hold shape even when subjected to high temperatures.

The most common among the molybdenum alloys is the titanium-zirconium-molybdenum alloy (TZM), which is a blend of 0.5% titanium and 0.08% zirconium, and about 90% molybdenum. This alloy exhibits strength even at very high temperatures, making it the perfect alloy for casting zinc.

2. Usages of Molybdenum Alloys

Among the refractory metals, molybdenum is the most commonly used. Its most popular application is as a strengthening alloy in the production of steel. Molybdenum alloys are usually found in the form of coils, sheets, rods, or bars. These materials are commonly used to manufacture steel, cast iron, and other engineered products used in automotive, stainless steel production, shipbuilding, aircraft and aerospace, and other specialty industries.

Molybdenum alloys have very high strength and stay stable even at a temperature as high as 1900°C. Such uniqueness contributes to the use of molybdenum alloys in furnaces used to melt glass, in the manufacture of X-ray anodes used for diagnostics, and in other high-temperature heating elements.

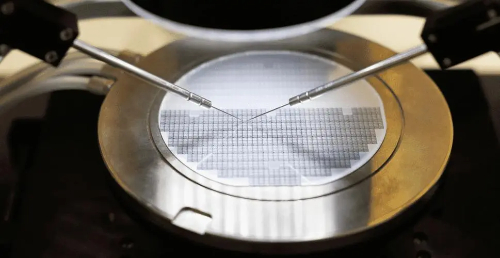

Moly is also alloyed with other metals such as tungsten (symbol W), copper (symbol Cu), and rhenium (symbol Re). Mo-W alloys are used for stirrers, piping, and pump impellers because of their high resistance against molten zinc. Mo-Cu alloys are used for applications requiring high conductivity, such as the production of electronic circuit boards. Mo-Re alloys are noted for their ductility and are used for rocket engine parts.

3. The Future of Molybdenum Alloys

Molybdenum and its alloys are used in various industries, from the traditional steel processing industry to the new emerging applications. Some of the new applications of molybdenum alloys include manufacturing cutting-edge electronic devices, LED lights, and high-efficiency solar cells.

Due to the properties that continue to make the moly element attractive, such as its excellent thermal conductivity and flexibility when used in various chemical environments, molybdenum alloys will continue to be used in other industries. Although there is not a lot of molybdenum supply in the world, it will continue to be an important element to impact global economies in the future.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of molybdenum alloys. If you want to learn more about Mo products, we would like to advise you to visit Stanford Advanced Materials (SAM) for more information.

Stanford Advanced Materials (SAM) is a worldwide supplier of molybdenum alloys and has over two decades of experience in the manufacture and sale of molybdenum products, providing high-quality products to meet our customers' R&D and production needs. As such, we are confident that SAM will be your favorite molybdenum supplier and business partner.