How Do Metal Materials Work in the Medical Field?

In recent years, metal materials seem to be the favorite in the medical field. Metal materials have many irreplaceable properties, which makes them widely used in diagnosis, treatment, replacement, repair and even enhancement of human function. The earliest use of metal materials can be traced back to the Phoenician's use of metal materials for filling teeth in the third or fourth century BC, however, it looks more like the orthodontic braces many children wear today because of its primitive methods. By the middle and late 19th century, advances in metallurgical technology had enabled people to acquire more of the properties of metals and to begin producing alloys on demand. In 1896, the medical profession first began to use nickel-plated steel screws to repair fractures.

Medical stainless steel

Steel is actually an iron-based alloy, and different formulations have resulted in a large number of steel materials with different properties. The price of steel has been very low since the great steel smelting in the west, besides that, steel has very attractive features, such as easy processing, high strength, corrosion resistance, etc. Medical stainless steel is very common in operating rooms. Operating knives, scissors, hemostatic forceps and so on are all stainless steel products.

Cobalt alloy

More than a decade ago, outdoor sports were very popular, just like today's marathon. However, many people who exercise too much burn out the cartilage in their joints, so they have to have artificial joints replaced in hospitals. The most commonly used artificial joint implant is cobalt alloy. The wear resistance of cobalt alloy is the best, and passivation film will be formed on the surface after implantation, which is suitable for long-term implantation.

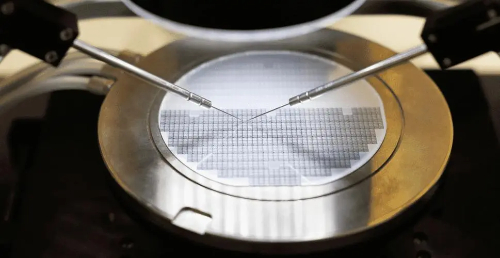

Titanium alloy

In the 1940s, titanium was found to be a lightweight, strong, and human-friendly metal. At present, the titanium alloy is used in bone grafting board, screw, plastic surgery, artificial heart membrane flap, dental fixation and so on in orthopedics department. It has become the most widely used metal material in the medical field.

However, although titanium alloy has excellent mechanical properties, its hardness is not as good as cobalt alloy and its surface abrasion resistance is not good. In particular, when titanium alloys are used in areas where wear is expected, the worn alloys can precipitate toxic vanadium ions, which can lead to poisoning. Now the research direction of titanium alloy is vanadium free.

Shape-memory alloys and precious metals

A shape-memory alloy (SMA) is an alloy that "remembers" its original shape and that when deformed returns to its pre-deformed shape when heated. At present, the shape-memory alloy is mainly nickel-titanium alloy, and the core of the application is the cardiovascular stent.

Precious metals are commonly silver, gold, and platinum. These materials are characterized by high inertia and little or no chemical reaction, which are often used in parts requiring long-term implantation. For example, gold teeth are used in the oral environment with certain digestive enzymes for a long time without affecting its luster. Besides that, metal tantalum, niobium and zirconium are similar in structure to titanium and are generally used as part of titanium alloy repair parts. However, these metals are expensive and cannot be used in large quantities.