Palladium on Silica: Catalytic Excellence

Introduction

Palladium on silica is a catalytic system that has garnered significant attention in the field of chemistry and catalysis. This powerful combination of palladium nanoparticles supported on a silica substrate offers a wide range of applications and holds great potential for catalytic transformations. In this article, we will explore the features, synthesis methods, and diverse applications of palladium on silica, providing a comprehensive understanding of its catalytic excellence.

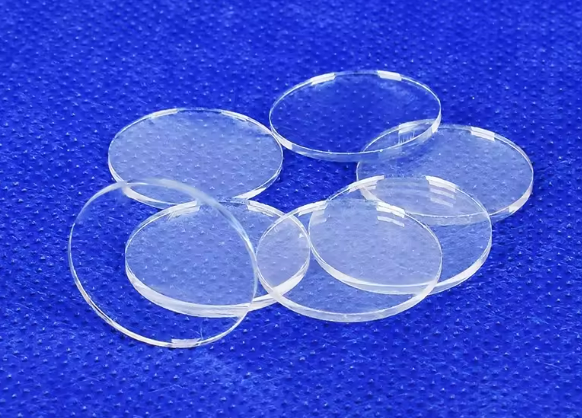

Figure 1. Palladium on Silica

What Is Palladium on Silica?

Palladium on silica refers to palladium nanoparticles immobilized or deposited onto a silica support material. Silica, or silicon dioxide (SiO2), is an ideal support due to its high surface area, thermal stability, and chemical inertness. Palladium, a transition metal, is well-known for its exceptional catalytic properties, making it a valuable component in many catalytic systems.

How to Synthesis Palladium on Silica?

There are several methods to prepare palladium on silica catalysts. One common approach involves impregnating a silica support material with a palladium precursor, followed by a reduction step to convert the precursor into palladium nanoparticles. Another method involves depositing palladium nanoparticles onto pre-formed silica supports using techniques like wet impregnation, deposition-precipitation, or co-precipitation. The choice of synthesis method can influence the size, dispersion, and stability of the palladium nanoparticles, thereby affecting the catalytic performance.

How to Use Palladium on Silica?

Palladium on silica is renowned for its remarkable capacity to facilitate hydrogenation, oxidation, cross-coupling, and the formation of carbon-carbon bonds in various reactions.

--Hydrogenation Reactions:

This catalyst is widely used in hydrogenation reactions, which involve the addition of hydrogen to unsaturated compounds. The catalytic system facilitates the reduction of various functional groups, including alkenes, alkynes, ketones, and nitro compounds. The high catalytic activity and selectivity of palladium nanoparticles on silica contribute to efficient hydrogenation processes in the pharmaceutical, chemical, and food industries.

--Cross-Coupling Reactions:

Palladium on silica is invaluable in cross-coupling reactions, a class of transformative reactions that involve the formation of carbon-carbon bonds. The well-known Suzuki-Miyaura, Heck, and Sonogashira reactions are examples of palladium-catalyzed cross-coupling reactions. The catalyst promotes the coupling of aryl or vinyl halides with suitable nucleophiles, enabling the synthesis of complex organic molecules with broad applications in drug discovery and materials science.

--C-H Activation:

This catalyst has been employed in C-H activation reactions for the functionalization of C-H bonds. This transformative process offers a direct and efficient method to modify organic molecules. Palladium on silica catalysts can selectively activate specific C-H bonds, allowing for site-selective functionalization and enabling the synthesis of complex organic compounds.

--Environmental Applications:

Palladium on silica catalysts have proven useful in environmental applications such as wastewater treatment and pollution control. They can facilitate the removal of pollutants, such as organic dyes or heavy metals, from contaminated water sources. Palladium nanoparticles on silica act as efficient catalysts in processes like catalytic oxidation, reduction, or degradation of pollutants, contributing to cleaner and safer environments.

Related reading: Common Reaction Types of Homogeneous Precious Metal Catalysts

What Are the Benefits of Palladium on Silica?

The combination of palladium and silica offers several key advantages in catalytic applications:

- High Catalytic Activity: Palladium nanoparticles possess excellent catalytic activity, allowing for efficient and selective transformations. The presence of palladium on silica enhances the catalytic performance, leading to accelerated reactions and improved yields.

- Stability and Reusability: Palladium on silica catalysts exhibit good stability, maintaining their catalytic activity over multiple reaction cycles. This durability allows for catalyst reuse, making it a cost-effective choice in industrial applications.

- Control and Selectivity: Palladium on silica catalysts can be finely tuned to achieve the desired selectivity in various reactions. The control over reaction conditions, particle size, and catalyst structure allows for the selective formation of specific products, reducing the formation of undesired by-products.

- Versatility: Palladium on silica catalyst finds applications in diverse chemical transformations, from hydrogenation to cross-coupling and C-H activation. This versatility makes them valuable tools in organic synthesis and industrial processes.

Conclusion

Palladium on silica is a powerful catalytic system that unlocks the potential for a wide range of transformations. Its versatility, high catalytic activity, stability, and selectivity make it an invaluable tool in various industries, including pharmaceuticals, chemicals, and environmental applications. By understanding the features, synthesis methods, and applications of palladium on silica, researchers and industrial practitioners can harness its potential to drive innovation, advance synthesis processes, and contribute to the development of sustainable chemical transformations.

Stanford Advanced Materials (SAM) is a leading supplier of high-quality palladium on silica, palladium on alumina, palladium on carbon, and other precious metal catalysts. Send us an inquiry if you are interested.