Tantalum Pentoxide in Electronics: A Key Ingredient for Miniaturization

In the ever-evolving world of electronics, one of the most compelling trends has been the continuous drive toward miniaturization. From smartphones and wearables to IoT devices and medical implants, the demand for smaller, more powerful electronic components has become a defining characteristic of the industry. At the heart of this miniaturization trend lies tantalum pentoxide, a vital and often unsung hero in modern electronic engineering.

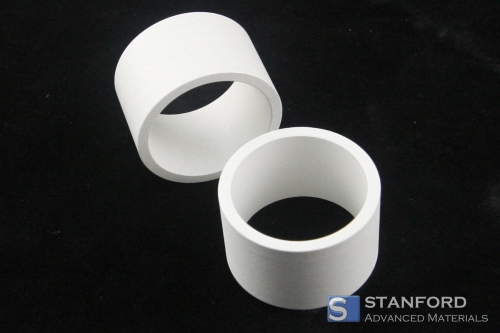

Tantalum pentoxide (Ta2O5) is a compound derived from the metal tantalum, a dense and highly corrosion-resistant element. It has found widespread use in the electronics industry, especially in the development of capacitors, as well as in the production of thin-film coatings and insulating layers in semiconductor devices. Its importance lies in its ability to offer high capacitance, stability, and reliability in a compact form, making it a linchpin in the quest for smaller, more efficient electronics.

The Role of Tantalum Pentoxide in Capacitors

Capacitors are passive electronic components that store and release electrical energy. They play a crucial role in various electronic applications, including power supplies, signal filtering, and timing circuits. Tantalum capacitors, in particular, have gained a reputation for their exceptional performance and reliability.

The secret to their success lies in tantalum pentoxide. This compound is used as the dielectric material in tantalum capacitors. The dielectric is the insulating material between the two conductive plates of a capacitor. The quality of the dielectric directly influences a capacitor's capacitance, voltage rating, and stability. Tantalum pentoxide, with its high dielectric constant, allows for a much higher capacitance value in a compact package compared to traditional aluminum electrolytic capacitors.

Tantalum capacitors are renowned for their high volumetric efficiency, meaning they can store a significant amount of energy in a small physical volume. This is a crucial feature for modern electronic devices where space is at a premium. As electronic gadgets become smaller, thinner, and more complex, the ability to pack more capacitance into a smaller footprint is invaluable. Tantalum capacitors, thanks to tantalum pentoxide, are the capacitors of choice in many applications.

Tantalum Pentoxide in Semiconductors

Beyond capacitors, tantalum pentoxide also plays a crucial role in semiconductor manufacturing. Semiconductors are the building blocks of all electronic devices, and they rely on a variety of materials to function correctly. Tantalum pentoxide is used in the production of thin-film capacitors and insulating layers in semiconductors.

These thin-film capacitors are essential for integrated circuits, as they help maintain the stability and performance of the electronic components. The use of tantalum pentoxide in these capacitors ensures high capacitance in a small area, which is vital for achieving the miniaturization goals of modern electronics.

Additionally, tantalum pentoxide serves as an insulating layer in semiconductor devices. In this capacity, it acts as a barrier to prevent unwanted electrical currents between different components of a semiconductor device. This insulating property is crucial for maintaining the integrity and reliability of these devices, especially as they become smaller and more densely packed.

Challenges and Considerations

While tantalum pentoxide offers numerous advantages in the pursuit of miniaturization, it's essential to consider the challenges associated with its use. Tantalum is a relatively rare and expensive material, which can drive up the cost of tantalum capacitors. However, the superior performance and reliability of these components often justify the investment.

Furthermore, the tantalum mining industry has faced ethical and environmental concerns in some regions, leading to calls for more responsible sourcing practices. Many manufacturers have responded to these concerns by implementing responsible sourcing and recycling programs.

What makes tantalum pentoxide such a crucial element in the drive for miniaturization?

Miniaturization of Capacitors: Tantalum Pentoxide capacitors, often referred to as tantalum capacitors, are widely used in electronic devices. These capacitors have a distinct advantage over their counterparts due to the high dielectric constant of tantalum pentoxide. This means they can store a larger charge in a smaller space, making them ideal for miniaturization. As electronic devices become smaller, the demand for capacitors that can deliver high capacitance in a compact form is on the rise. Tantalum pentoxide capacitors meet this need effectively.

Increased Energy Density: As the electronic devices we use daily, from smartphones to wearables, become more compact, there is an increasing demand for batteries that can deliver high energy density. Tantalum pentoxide plays a critical role in improving the energy density of batteries. Enhancing the performance of lithium-ion batteries and supercapacitors allows for more power to be stored in a smaller volume. This not only leads to longer battery life but also allows for the development of smaller and more efficient devices.

Improved Semiconductor Performance: Tantalum pentoxide is also used in the production of thin-film transistors (TFTs) and other semiconductor devices. It acts as a high-k dielectric material, which means it can insulate the transistor's gate and effectively increase its performance. This is crucial in the manufacturing of smaller and more powerful semiconductor devices like those found in modern processors and memory chips.

Durability and Reliability: Tantalum pentoxide is known for its robustness and resistance to harsh environmental conditions. This makes it an ideal choice for miniaturized devices that need to withstand extreme temperatures, humidity, and other challenging situations. Its long-term stability ensures that miniaturized electronic components remain reliable and durable over time.

Compatibility with Nanotechnology: With the growing influence of nanotechnology in the electronics industry, tantalum pentoxide plays a pivotal role in this emerging field. Its compatibility with nanoscale fabrication techniques enables the creation of exceptionally small and efficient electronic components.

In conclusion, tantalum pentoxide is a key ingredient in the world of electronics, enabling the miniaturization of electronic devices while maintaining high performance and reliability. Its unique properties, such as high capacitance, stability, and insulating capabilities, make it an indispensable component in the production of capacitors and semiconductor devices. As the demand for smaller, more powerful electronics continues to grow, tantalum pentoxide will remain a crucial player in the ever-shrinking world of electronic components.