Thin to Thick: Beryllium Sheets in Cutting-Edge Applications

Introduction

In the realm of advanced materials driving technological innovation, beryllium stands out for its exceptional properties and versatility. This rare element comes with its remarkable combination of lightness, stiffness, and thermal conductivity. It is increasingly pivotal in a wide range of cutting-edge applications.

Central to its utility are the two principal forms: thin beryllium sheets and thick beryllium sheets. Each form caters to specific demands across various industries, from aerospace and defense to electronics and nuclear energy. This article explores the distinct characteristics, applications, advantages, and challenges associated with these two sheets.

Understanding Beryllium Sheets

1. The Basics of Beryllium

Before delving into the applications, it’s crucial to understand what sets beryllium apart. Beryllium is lighter than aluminum yet has more than six times the specific stiffness of steel, making it an incredibly efficient structural material for applications requiring minimal weight and high rigidity. Additionally, it has an exceptional thermal expansion coefficient, closely matching that of silicon, and serves as an excellent neutron moderator, making it indispensable in nuclear reactors.

1. From Aerospace to Particle Physics

- Aerospace and Defense: Beryllium's low density and high strength make it perfect for aerospace and defense applications, including the construction of high-speed aircraft, missiles, and satellite components. Its resilience to extreme thermal changes is crucial for space-bound elements.

- Telecommunications: Be sheets are critical in making durable and efficient components like springs, switches, and connectors for mobile devices and other telecommunications equipment, thanks to their excellent electrical conductivity and corrosion resistance.

- Medical Technology: In medical imaging, Be's transparency to X-rays enhances the quality of X-ray images, allowing for clearer diagnostics with reduced radiation exposure to patients.

- Particle Physics and Nuclear Energy: Used in particle accelerators and nuclear reactors, Be sheets are essential for their low atomic number, high melting point, and neutron moderation, facilitating safe and efficient nuclear reactions.

Related Reading: 6 Common Uses Of Beryllium

Thin Beryllium Sheets vs Thick Beryllium Sheets

1. Characteristics and Production Techniques

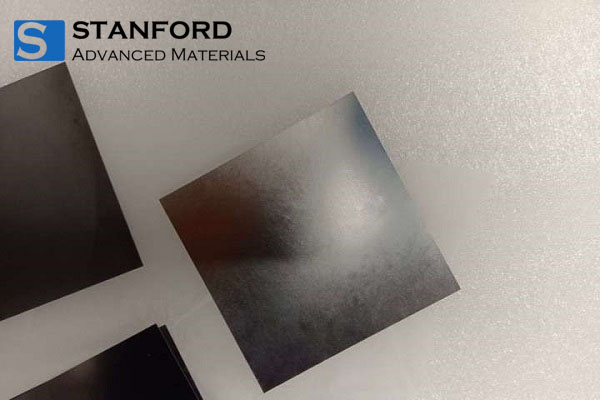

Thin beryllium sheets, often less than 0.1 mm in thickness, are celebrated for their flexibility and lightweight nature. Produced through precision rolling and machining, these sheets retain beryllium's inherent qualities while being especially prized for their electrical conductivity and resistance to corrosion.

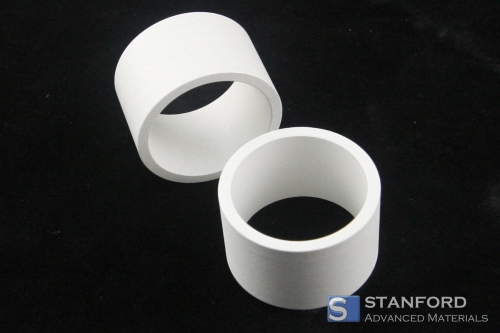

In contrast, thick beryllium sheets—those exceeding 1 mm—offer robustness and durability, produced via heavy-duty rolling and annealing processes to ensure uniformity and stress relief. These thicker sheets excel in applications requiring a high modulus of elasticity and superior thermal stability.

1. Diverse Applications across Industries

Thin beryllium sheets are employed across industries such as electronics, aerospace, and medical technology for their unique combination of electrical conductivity, thermal stability, and X-ray transparency.

- In the realm of electronics and telecommunications, these sheets are integral to the manufacturing of springs, switches, and connectors found in mobile devices, computers, and other pieces of electronic equipment, offering unparalleled electrical conductivity and enhanced durability.

- Within the aerospace industry, thin beryllium sheets are crucial for constructing lightweight structures in aircraft and satellites. Their resistance to thermal expansion and exceptional stiffness contribute significantly to improved performance.

- For X-ray technology, beryllium's ability to allow X-rays to pass through with minimal scattering makes it an ideal material for X-ray windows. This property significantly enhances the clarity of X-ray images while simultaneously reducing the radiation exposure to patients.

Related Video:

Thick beryllium sheets are crucial in applications requiring robustness and thermal stability, such as in nuclear reactors, aerospace structures, and scientific instrumentation.

- Within nuclear applications, these sheets are essential for their role in nuclear reactors and fusion technology. They serve as neutron reflectors and moderators, chosen for their low absorption cross-section for thermal neutrons and their ability to withstand high temperatures without melting.

- In aerospace and defense, thick beryllium sheets are utilized for parts that require a superior stiffness-to-weight ratio and exceptional thermal stability. This includes the manufacture of satellite mirrors, structural frames, and various aerospace instruments, where their properties significantly enhance performance and reliability.

- For scientific research, these sheets are fundamental in creating mirrors and optical components used in telescopes and spectrometers. Their dimensional stability and lightness are invaluable for ensuring precise measurements and facilitating groundbreaking discoveries in the field.

2. Advantages and Challenges

While the advantages of beryllium sheets are compelling, their use is not without challenges. The health risks associated with beryllium dust during production and machining processes are a significant concern, necessitating stringent safety measures to protect workers.

Furthermore, the high cost of beryllium, particularly for thick sheets, poses a barrier to its widespread adoption, limiting its application to areas where its unique properties are absolutely essential.

3. The Future of Beryllium Sheets in Technology

The future of beryllium sheets in technological applications appears promising.

- As industries continue to evolve, the demand for materials that offer a blend of lightweight properties, strength, and thermal stability is set to rise.

- Innovations in manufacturing techniques aim not only to mitigate the health risks associated with beryllium but also to reduce costs, thereby expanding its accessibility and applications.

- Research into beryllium alloys and composite materials may further broaden the spectrum of its use, capitalizing on the strengths of both thin and thick sheets.

For more details, here's a concise summary table that encapsulates the key differences and applications of these two beryllium sheets. Stanford Advanced Materials (SAM), a global leader in the supply of beryllium products, currently offers a wide range of beryllium plates and sheets for sale. With options available in various sizes and thicknesses, SAM caters to diverse needs at highly competitive prices. Please check our homepage for more information.

Table 1. Thin Beryllium Sheets vs Thick Beryllium Sheets

|

Feature |

||

|

Thickness |

Typically less than 0.1 mm |

Generally thicker than 1 mm |

|

Production Techniques |

Precision rolling and machining |

Specialized heavy-duty rolling and annealing |

|

Primary Properties |

Flexibility, excellent electrical conductivity, and corrosion resistance |

Structural robustness, high modulus of elasticity, and thermal stability |

|

Key Applications |

|

|

|

Challenges |

Health risks from beryllium dust, necessitating strict safety protocols |

Higher material and processing costs, health risks similar to thin sheets |

Conclusion

In a word, while thin beryllium sheets and thick beryllium sheets serve different purposes, they both contribute significantly to technological advancements across industries. Their unique properties enable innovations in aerospace, nuclear energy, electronics, and beyond, highlighting the importance of ongoing research and development in materials science to harness their full potential while mitigating associated risks.