3 Important Things about Tantalum Capacitor

Introduction

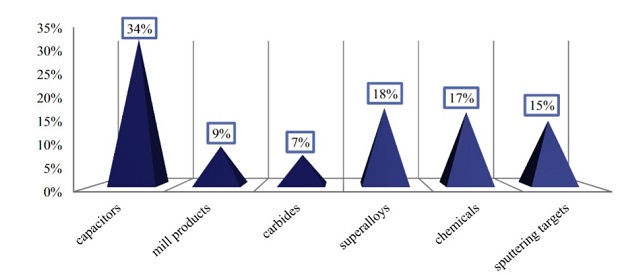

Tantalum (Ta) is a rare, hard, blue-gray, and lustrous transition metal that is highly corrosion-resistant and conductive to heat and electricity. It has excellent immunity to aggressive aqua regia under 150℃. Due to its good physical and chemical properties, Tantalum is mainly used in the field of electronics, alloys, and other areas. Figure 1 shows tantalum’s product shipment in 2016 [1]. Most tantalum is used in capacitors as anodes that belong to electronics, and others are mainly used in alloys, chemicals, and sputtering targets. In 2021, about 70% demand for tantalum is from the electronics industry: anodes for capacitors, semiconductor targets, and sintering liners for anodes [2]. Let’s first talk about tantalum capacitors.

Figure 1: Tantalum’s product shipment in 2016 [1]

How is Tantalum Capacitor Made?

Just like other capacitors, a tantalum capacitor has 3 components: an anode, a cathode, and some electrolyte. Pure tantalum powder and wires are used to make the anode part.

By compressing tantalum powder around a tantalum wire, we get a “pellet” form of tantalum. Then sinter the pellet at about 1200 to 1800℃ to eliminate impurities. During this process, the powder also takes on a porous structure, which can increase its capacitance value. In other words, tantalum capacitors have a higher capacitance value/ volume compared with other capacitors such as Aluminum capacitors.

After sintering, a dielectric is formed outside the tantalum particle surfaces by transforming the outside tantalum layer into Ta2O5. This process is called anodization. The dielectric thickness is directly related to the voltage proof of capacitors. Each capacitor should have a safety margin oxide layer thickness to make sure reliable functionality.

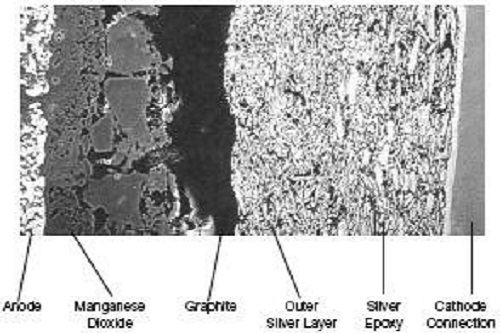

The last step is to add a cathode outside the dielectric. Wet tantalum capacitors use a liquid electrolyte to submerge the tantalum part and an enclosure covers wet tantalum capacitors. The enclosure and the liquid electrolyte work as the cathode in the wet tantalum capacitor. For the solid tantalum capacitor, dipping the anode into Mn(NO3)2 solution and baking at about 250℃ will let a MnO2 layer form outside the dielectric. Repeat several times till an enough thick MnO2 layer is formed outside the “pellet”. Then dip it into graphite and silver to give a good connection from the MnO2 cathode to the external cathode termination. Figure 2 gives you a briefer view of the solid tantalum capacitor.

Figure 2: cross-section of a solid tantalum capacitor

Advantages and Disadvantages of Tantalum Capacitor

Advantages

Tantalum capacitors have superior frequency characteristics and longer lifetime compared with aluminum capacitors or ceramic capacitors. Their equivalent series resistance is also smaller, which means larger currents can pass through the capacitor with less heat. What’s more, tantalum capacitors offer the highest capacitance per volume, as mentioned before. Thanks to these advantages, tantalum capacitors are popular in electronic fields such as laptops, smartphones, and so on.

Disadvantages

However, tantalum capacitors are not as widely used as aluminum capacitors, multilayer ceramic capacitors (MLCCs), or even niobium capacitors. One reason is that the supply and price of tantalum metal are unstable. In some cases, people start to use MLCCs to replace small tantalum capacitors, and aluminum capacitors to replace large tantalum capacitors.

Since they are polarized, tantalum capacitors can only be used in DC current other than AC current. Additionally, when the anodes contact MnO2 cathodes during voltage spikes, tantalum capacitors may have a dangerous failure mode, such as chemical reaction that producing smoke and flame. To prevent it, tantalum capacitors should be used with current limiters or thermal fuses together.

Applications of Tantalum Capacitor

Tantalum capacitors are used mainly due to their highest capacitance/ volume, good stability, and superior frequency characteristics. Tantalum capacitors can be used to replace aluminum electrolytic in military applications because of their stability in capacitance over time. Medical electronics also use tantalum capacitors for this advantage. Among electronic products, Desktop PC and notebooks use the largest amount of tantalum capacitors. And surprisingly, smartphones and mobile phones use very few amounts of tantalum capacitors by comparison.

Tantalum Recycling

With the increasing consumption of tantalum products, lots of waste that contain tantalum is produced in large quantity. Production waste during the manufacturing of super alloy & sputtering targets and end-life discards from the electronic industry increased significantly. In contrast, the gap between demand and supply tantalum becomes bigger and bigger. To close this gap, recycling tantalum waste starts to develop again.

Recycling can be divided into 2 parts: pre-consuming recycling and post-consuming recycling [3]. Most tantalum is recycled from pre-production scrap because of its low contamination and low difficulties. Pre-consuming recycling can efficiently improve the total production process with mineral waste generation. Tantalum concentration, cleaning cost, size, and economy are the main factors affecting recycling strategies.

Post-consuming recycling for tantalum developed not very well due to the low concentration of tantalum compared to other metals such as Cu, and Au. For pyrometallurgical tantalum products, the process of post-consuming recycling of tantalum is very complicated. Smaller-size tantalum capacitors make this situation even worse. More research should be taken to create an economic and environment-friendly method to recycle post-consuming tantalum products.

Citation

- Agrawal, M., Singh, R., Ranitović, M., Kamberovic, Z., Ekberg, C., & Singh, K. K. (2021). Global market trends of tantalum and recycling methods from Waste Tantalum Capacitors: A review. Sustainable Materials and Technologies, 29, e00323.

- Zogbi, D. M. (2021, May 10). The tantalum supply chain: 2021 global market update. TTI, Inc. Retrieved January 4, 2023, from https://www.tti.com/content/ttiinc/en/resources/marketeye/categories/passives/me-zogbi-20211005.html

- Agrawal, M., Singh, R., Ranitović, M., Kamberovic, Z., Ekberg, C., & Singh, K. K. (2021). Global market trends of tantalum and recycling methods from Waste Tantalum Capacitors: A review. Sustainable Materials and Technologies, 29, e00323.