The Application of Zirconium Products

What is Zirconium?

Zirconium, chemical symbol Zr, atomic number 40, melting point 1852°C, is one of the high melting point metals. It absorbs oxygen in the air to form an oxide film, becoming silver-white in color.

What are the Zirconium compound applications?

Zirconium compounds are mainly used in industrial production in the form of zirconium silicate, zirconium carbonate, zirconium oxychloride, and zirconia. The main component of zircon sand is zirconium silicate. After grinding, sintering, and powderization, the zircon sand is made into the ceramic glaze, which has good chemical stability and is not affected by the ceramic sintering atmosphere and can significantly improve the ceramic glaze hardness and is widely used in building ceramics, sanitary ceramics, and daily ceramics industries.

Zirconium carbonate is an important raw material for the textile and paper industry. It is used as a surface auxiliary for the production of paper. In addition, as an additive and waterproofing agent, it is widely used in the cosmetics industry.

Zirconium oxychloride can be used to produce rubber additives, metal surface treatment agents, and paint desiccants. Zirconia and composite zirconia ceramics can endure high temperatures and are highly stable. They don’t have a reaction with alkaline and most acidic solutions and are suitable for the production of ceramic crucibles and other precision ceramics.

What are the pure zirconium metal applications?

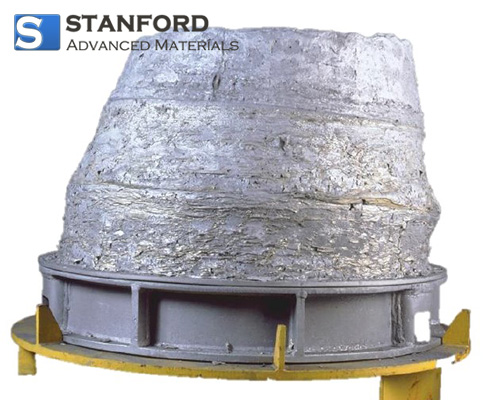

Metal pure zirconium can be divided into industrial grade, firearm grade, and nuclear grade. It is mainly sponge zirconium. Industrial-grade zirconium metal is mainly used in the production of corrosion-resistant equipment, including pumps, heat exchangers, valve pipes, nozzles, and so on. Zirconium wire can be used to produce a grid plate bracket and cathode holder.

Zirconium has the effect of deoxidation, nitrogen removal, and desulfurization. It is widely used in metal additives to enhance the hardness and strength of the alloy. For example, armored vehicles and tanks mostly use zirconium-containing armor steel. High-voltage wire mostly uses zirconium-containing copper wire, which substantially increases the melting point without weakening the conductivity.

Firearms grade sponge zirconium powder

Firearms-grade sponge zirconium powder is extremely flammable and is mostly used in the production of fire-inducing materials, flash powder, and military blowing agents. Nuclear-grade zirconium has a higher purity and is an important military strategic metal that is used for the production of structural materials and components for aircraft carriers, submarines, and power generation reactors.