LaB6 Cathodes Used in Electron Microscopes

Introduction

Lanthanum hexaboride (LaB6, lanthanum boride, or LaB) is a chemical compound composed of lanthanum and boron, and the lanthanum hexaboride target is a type of ceramic sputtering target made from the same material. Both of them are widely used in optical apparatus and techniques like electron microscopes, electron lithography, etc. This article is going to focus on the application of lanthanum boride cathodes and lanthanum boride coatings in electron microscopes with a successful case.

Figure 1 Lanthanum Hexaboride Sputter Targets

Features and Uses of LaB6 Sputter Targets

--Features

Lanthanum hexaboride sputter targets share similar features with LaB6 ceramic. The purple-violet ceramic has a high melting point of 2483K. LaB6 is insoluble in water and hydrochloric acid. It is quite tough with a Mohs hardness of 9.5. Additionally, because of its low work function of near 2.70 eV and high electron emissivity, LaB6 could produce high currents even at lower temperatures. The material also stands out for its low evaporation rate.

--Uses

Thanks to these desirable properties, lanthanum hexaboride became the material of choice for cathodes in electron microscopes, scanning electron microscopes (SEM), and electron beam lithography. You can also apply high-purity lanthanum hexaboride sputter targets to manufacture LaB6 thin-film coatings. This hexaboride also has many other applications, including radar aerospace, electronics, X-ray powder diffraction, and most importantly, it is used as a cathode material for electron microscopes.

Related reading: Features and Applications of LaB6 Filaments

LaB6 Cathodes VS Tungsten Cathodes

--What Are LaB6 Cathodes?

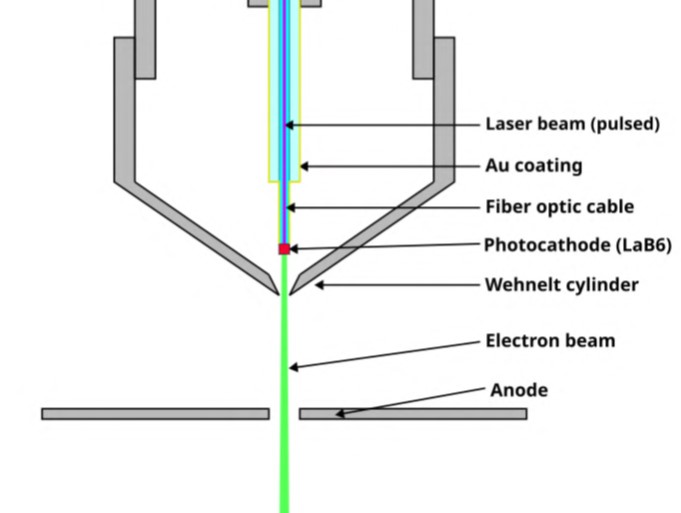

Electron sources are of great importance to electron microscopes. A detector system is needed for the electron microscope’s performance. The whole optical system consists of a cathode and one or two anodes. Besides, there are relatively large spaces in between. The complete structure of a detector system is shown in figure 2 below.

- The cathode serves as the electron source. Lanthanum hexaboride is an ideal option to make such cathodes. Coating the cathodes with LaB6 thin films also works.

- The anode is set to attract electrons and passes them on.

- During the processing, electrons escape the solid surface of cathodes once they get enough energy from heating. They are accelerated thereafter.

Figure 2 Lanthanum Hexaboride Cathode Structure

-- LaB6 Cathodes VS Tungsten Cathodes

A range of materials like lanthanum hexaboride, cerium hexaboride, and tungsten are employed to make cathodes or cathode coatings for better electron sources. Yet, LaB6 has the following benefits over other cathode materials. Here we compare Lab6 cathodes with tungsten cathodes.

Tungsten:

- Tungsten turns to have a shorter life because it evaporates and breaks at last.

- Tungsten cathode is not recommended for optical devices. It may result in low brightness and poor image quality under high-temperature conditions.

Lanthanum Hexaboride:

- LaB6 cathodes have a longer life since they are less prone to evaporation.

- LaB6 has higher brightness because they need lower temperatures to emit electrons. These hexaboride cathodes are around 10 times “brighter” than tungsten cathodes.

Lanthanum hexaboride is superior to tungsten as a cathode material in various respects. Its only downside may be that it is more expensive than tungsten. But this does not prevent LaB6 from becoming a popular cathode material for electron microscopes.

Case Study: LaB6 Cathodes Used in Electron Microscopes

--The Challenge

Stanford Advanced Materials (SAM) has been supplying high-quality materials for laboratories for several years. Recently, a German customer asked us for some lanthanum hexaboride sputter targets for optical projects. He is a researcher specializing in the production of self-made optical components such as laser equipment and electron microscopes. He was trying to make a detector system that could measure cathodoluminescence and photoluminescence (See figure 3). He decided to use lanthanum hexaboride instead of tungsten for a novel electron source.

Figure 3 The Detector System

--The Solution

SAM is quite glad to assist our customers to complete their scientific studies. We also feel excited to learn about these projects and optical instruments.

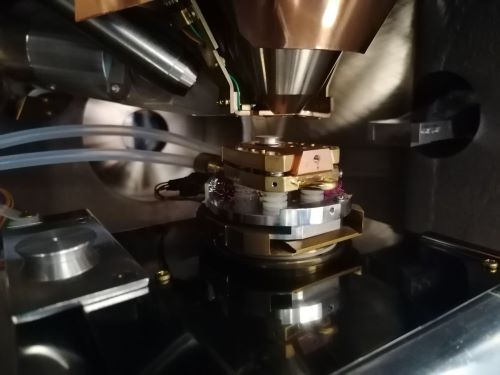

This time, our customer introduced his projects to us and asked for one piece of LaB6 sputter target. The dimension was 1" Dia. x 2-3 mm Thick, and the purity was 99.5%. He also attached a picture of the electron microscope in his project in emails (See figure 4). Finally, his projects went well with the LaB6 target we provided.

Figure 4 Our Customer’s Scanning Electron Microscope

--The Results

Our customer gained lanthanum hexaboride material, and he found that these sputter targets have extra advantages. The researcher claimed as follows.

- Due to the low work function of LaB6, a cheaper laser can be used since other coating materials require several nonlinear processes.

- Compared with other low work function materials, the degradation of LaB6 coating is rather low, which allows for easier handling and transformation.

Conclusion

Lanthanum hexaboride has numerous benefits over other materials when it is applied to make cathodes or cathode coating for electron microscopes. Stanford Advanced Material is a leading supplier of a variety of ceramics, chemicals, magnets, metals, and alloys. Send us an inquiry if you are interested in lanthanum hexaboride or other advanced materials. You can also check our homepage for more information.