Ultimate Guide to Heat Resistant 3D Printing Materials: Top 10 Picks

Introduction

The world of 3D printing has expanded rapidly, offering a plethora of material options, especially for applications requiring heat resistance. Whether it's for automotive parts, aerospace components, or consumer goods, choosing the right heat-resistant material is crucial for success. In this guide, we'll explore the top 10 picks for heat-resistant 3D printing materials, delving into their properties, applications, and what makes them stand out.

1. ABS (Acrylonitrile Butadiene Styrene)

ABS is a thermoplastic polymer composed of acrylonitrile, butadiene, and styrene molecules. It combines the rigidity of acrylonitrile and styrene polymers with the toughness of polybutadiene rubber. The result is a material that exhibits high impact resistance, good mechanical toughness, and a balance of hardness and gloss. ABS is also resistant to aqueous acids, alkalis, concentrated hydrochloric and phosphoric acids, alcohols, and animal, vegetable, and mineral oils, but it has poor resistance to solvents.

Technology: Fused Deposition Modeling (FDM)

Main Characteristics: Good strength, heat resistance, and ductility.

Applications: Automotive components, consumer goods, and electronic enclosures.

2. ULTEM (PEI - Polyetherimide)

ULTEM, or polyetherimide, is a high-performance engineering thermoplastic characterized by its amber translucent color. It offers a unique combination of high mechanical strength, broad chemical resistance, high dielectric strength, and excellent thermal stability. ULTEM maintains its properties over a wide temperature range and exhibits inherently flame retardant properties. It's also known for its good dimensional stability and electrical insulating properties.

Technology: FDM, SLS (Selective Laser Sintering)

Main Characteristics: High heat resistance, strength, and flame retardancy.

Applications: Aerospace and automotive components, medical devices, and electrical parts.

3. PP (Polypropylene)

Polypropylene is a lightweight, durable thermoplastic polymer that is recognized for its resistance to a broad range of chemicals, including solvents, bases, and acids. It has a high melting point, making it suitable for items that may be subjected to heat. PP is known for its flexibility, excellent electrical insulation, and good fatigue resistance. It is often used in applications that require bending repeatedly like living hinges.

Technology: FDM, SLS

Main Characteristics: High fatigue resistance, elasticity, and chemical resistance.

Applications: Automotive parts, consumer goods, and packaging materials.

4. Metal Filaments

Metal filaments are a blend of fine metal powders with a plastic polymer binder. They enable metal 3D printing by combining traditional filament extrusion with post-processing techniques like sintering. These filaments can produce parts with metal-like properties, including thermal and electrical conductivity. The final parts often require sintering in a high-temperature furnace to burn away the binder and fuse the metal particles together, resulting in a dense, metal part.

Technology: FDM for composite filaments, Direct Metal Laser Sintering (DMLS) for full metal parts.

Main Characteristics: High strength and thermal resistance; requires post-processing.

Applications: Aerospace components, automotive parts, and specialized tooling.

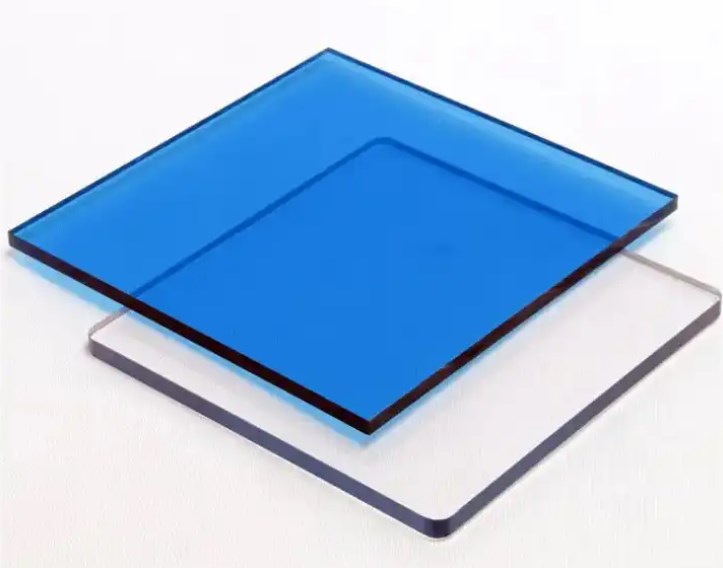

5. Polycarbonate (PC)

Polycarbonate is a high-performance thermoplastic known for its exceptional transparency, impact resistance, and heat resistance. It can transmit over 90% of light, as clear as glass, and is virtually unbreakable. PC is also temperature-resistant and can withstand extreme conditions while maintaining its properties. It's a versatile material used in a wide range of applications that require high performance and reliability.

Technology: FDM, SLA (Stereolithography)

Main Characteristics: Excellent toughness, heat resistance, and optical properties.

Applications: Protective gear, automotive components, and optical lenses.

6. PEEK (Polyether Ether Ketone)

PEEK is a semi-crystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained at high temperatures. It is one of the few plastics compatible with ultra-high vacuum applications. PEEK is highly resistant to thermal degradation as well as attack by both organic and aqueous environments. It is widely used in demanding engineering applications, especially those that require a high strength-to-weight ratio.

Technology: FDM, SLS

Main Characteristics: Exceptional thermal stability, chemical resistance, and mechanical strength.

Applications: Aerospace, medical implants, and high-performance automotive parts.

7. Aluminium AlSi10Mg

Aluminium AlSi10Mg is a common aluminum alloy in additive manufacturing. It combines aluminum's lightweight properties with silicon's high thermal conductivity and magnesium's strength. This alloy is known for its good ductility, excellent strength-to-weight ratio, and thermal properties. It is typically used in applications that require a high level of corrosion resistance and weldability.

Technology: Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM)

Main Characteristics: Lightweight, good thermal properties, and corrosion resistance.

Applications: Automotive parts, aerospace components, and consumer electronics.

8. Stainless Steel 316L

Stainless Steel 316L is a molybdenum-bearing austenitic stainless steel with enhanced resistance to chloride ion corrosion compared to other chromium-nickel stainless steels. It's known for its excellent toughness, even at cryogenic temperatures. This type of steel is commonly used in environments with harsh chemicals and is widely used in the food and medical industries.

Technology: DMLS, SLM

Main Characteristics: High corrosion resistance, mechanical properties, and weldability.

Applications: Medical devices, marine applications, and chemical processing equipment.

9. Inconel 718

Inconel 718 is a nickel-chromium alloy used for its high strength, excellent corrosion resistance, and ability to withstand extreme temperatures. This superalloy is known for its good tensile, fatigue, creep, and rupture strength at temperatures up to about 700°C (1290°F). It is commonly used in high-stress environments like gas turbines, rocket engines, and nuclear reactors.

Technology: DMLS, SLM

Main Characteristics: Excellent mechanical strength, corrosion resistance, and thermal stability.

Applications: Aerospace engine components, gas turbines, and high-temperature applications.

10. Carbon Fiber

Carbon fiber is composed of strands of carbon atoms aligned in a crystalline formation. It's known for its high stiffness, high tensile strength, low weight, high chemical resistance, high temperature tolerance, and low thermal expansion. These properties make carbon fiber very popular in aerospace, civil engineering, military, and motorsports, along with other competition sports.

Technology: Often used in composite materials in FDM or in reinforced filaments.

Main Characteristics: High strength-to-weight ratio, rigidity, and thermal conductivity.

Applications: Aerospace, automotive, and sports equipment.

Properties of Heat Resistant 3D Printing Materials

Here is the table containing the melting point, glass transition temperature, and tensile strength of the ten heat-resistant 3D printing materials:

|

Material |

Melting Point |

Glass Transition Temperature |

Tensile Strength |

|

ABS |

200°C |

105°C |

42.5 – 44.8 MPa |

|

ULTEM (PEI) |

340°C |

216°C |

105 MPa |

|

PP (Polypropylene) |

160 - 170°C |

-10°C |

32 - 40 MPa |

|

Metal Filaments |

Varies (depends on the specific metal) |

Varies |

Varies |

|

PC |

230 – 260°C |

147°C |

60 MPa |

|

PEEK |

343°C |

143°C |

110 MPa |

|

Aluminium AlSi10Mg |

670°C |

Not applicable |

450 MPa |

|

Stainless Steel 316L |

1,400°C |

Not applicable |

520 – 690 MPa |

|

Inconel 718 |

1,370 – 1,430°C |

Not applicable |

965 MPa |

|

Carbon Fiber |

Not applicable |

Not applicable |

3,500 – 7,000 MPa (for carbon fiber composites) |

Please note:

For materials like Metal Filaments and Carbon Fiber, the properties can vary significantly depending on the specific type or composite material.

The "Not applicable" designation is used for materials where a specific property (like melting point for Carbon Fiber) is not relevant or does not have a defined value.

Cost of Heat Resistant 3D Printing Materials

Here is the table presenting a cost comparison for the specified heat-resistant 3D printing materials:

|

Material |

Approximate Cost |

Price Range per kg |

|

ABS |

Low to moderate |

$20 - $100 |

|

ULTEM (PEI) |

Moderate to high |

$100 - $200 |

|

PP (Polypropylene) |

Low to moderate |

$50 - $100 |

|

Metal Filaments |

High |

$100 - $1000 |

|

PC |

Moderate to high |

$50 - $1000 |

|

PEEK |

high |

$300 - $1000 |

|

Aluminium AlSi10Mg |

High |

$200 - $1000 |

|

Stainless Steel 316L |

Moderate |

$50 - $1000 |

|

Inconel 718 |

high |

$300 - $1000 |

|

Carbon Fiber Filaments |

Moderate to high |

$100 - $1000 |

This table provides an overview of the cost ranges for each material, categorized from low to very high. Keep in mind that these prices are approximate and can vary based on factors like quality, supplier, location, and market conditions. For the most accurate and up-to-date pricing, it is recommended to contact us.

Conclusion

Choosing the right heat-resistant material for 3D printing depends on the specific requirements of your application, including temperature exposure, mechanical stresses, and environmental conditions. Each of these top 10 materials offers unique properties and advantages. By understanding these, you can unlock the full potential of 3D printing for high-temperature applications, pushing the boundaries of innovation and design.