Case Study: Silicon Carbide Plates for Advanced Armor Solutions

Introduction

In today's ever-evolving landscape of defense and security, the paramount task is to protect personnel and assets against modern threats. Silicon Carbide Plates, renowned for their exceptional hardness and durability, have emerged as revolutionary materials in the development of advanced armor solutions. This article explores the pivotal role played by these plates in enhancing defense strategies, safeguarding lives, and fortifying military assets.

Figure 1. The Defense Industry [1]

Understanding Silicon Carbide Plates

Silicon Carbide (SiC) Plates are a type of protective material used in defense and military applications. They are designed to offer exceptional resistance to various threats, including ballistic projectiles, high-velocity fragments, and even chemical agents.

Typically, they are made from a composite material that combines silicon carbide ceramics with other materials like boron carbide or high-strength fibers such as aramid (e.g., Kevlar) or ultra-high-molecular-weight polyethylene (UHMWPE). The SiC ceramic component provides excellent hardness and protection against ballistic threats, while the additional materials can enhance flexibility, impact resistance, and overall performance.

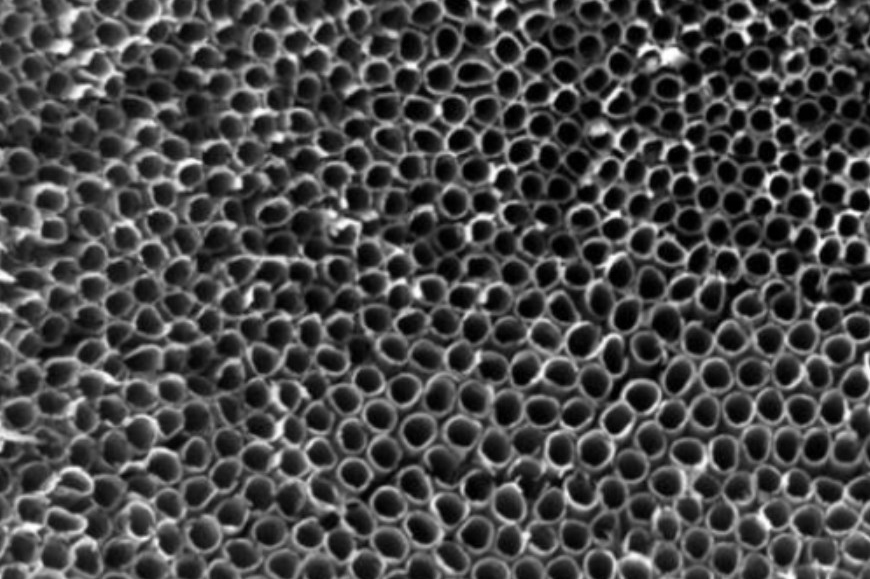

![]()

Figure 2. Silicon Carbide Plates

Applications of Silicon Carbide Plates Used in the Defense Industry

These materials find extensive application across a multitude of industries.

1. Ballistic Protection: Silicon Carbide Plates are widely used as inserts or plates in body armor systems to protect against bullets, shrapnel, and other ballistic threats. These plates can be incorporated into tactical vests, helmets, and other protective gear worn by military personnel, law enforcement officers, and security personnel.

2. Vehicle Armor: SiC Plates are also used to reinforce the armor of military vehicles, including tanks, armored personnel carriers, and armored cars. The high hardness and lightweight nature of silicon carbide make it suitable for protecting vehicles without adding excessive weight.

3. Aircraft Armor: In military aviation, these plates may be used as armor components in helicopters, aircraft, and unmanned aerial vehicles (UAVs) to protect critical systems and crew members from threats like small arms fire and shrapnel.

4. Shields and Barricades: These plates are employed in the construction of ballistic shields and barricades used by law enforcement agencies and security teams during high-risk situations, such as hostage rescues or riot control.

Advantages of Silicon Carbide Plates Used in the Defense Industry

These Silicon Carbide Components offer several significant advantages in the defense industry:

High Hardness: SiC is one of the hardest-known ceramics, offering excellent resistance to penetration by projectiles and fragments.

Lightweight: SiC Plates are relatively lightweight compared to some other armor materials, allowing for improved mobility and comfort for the wearer.

Multi-Threat Protection: Silicon Carbide Plates are effective not only against bullets but also armor-piercing rounds and high-velocity fragments.

Chemical Resistance: SiC is also resistant to chemical agents, providing additional protection against certain chemical threats.

Durability: These plates have a long service life due to their resistance to wear, corrosion, and degradation.

Conclusion

In summary, Silicon Carbide Plates are crucial components of modern protective gear and armored vehicles, thanks to their exceptional hardness, lightweight nature, and multi-threat protection capabilities. These plates are continually developed and improved to meet the evolving needs of defense and security forces.

Stanford Advanced Materials (SAM) is a trusted supplier of Silicon Carbide Products. Customization is also welcome. Send us an inquiry if you are interested.

Reference:

[1] Mobile Defense. (2023, August 2). In Wikipedia. https://en.wikipedia.org/wiki/Mobile_Defense