Tantalum Marker Bands: Applications and Significance

Introduction

Tantalum marker bands are often used in medical and industrial settings. These marker bands play a crucial role in various applications where precision and durability are of utmost importance. These small, cylindrical components are made from tantalum, which is known for its corrosion resistance, biocompatibility, and radiopacity. In this article, we will explore the diverse applications of tantalum marker bands and their significance in different fields.

Figure 1. Tantalum Marker Bands

1. Medical Devices:

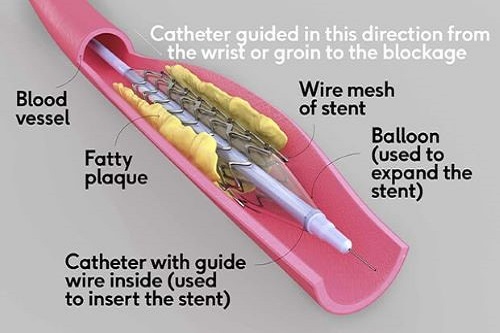

First, tantalum marker bands are commonly used in various medical applications, including catheters, stents, and other implantable devices. These small components help with localization and visualization during medical procedures.

Figure 2. Catheters and Stents [1]

l Vascular Interventions: In interventional cardiology and radiology, these marker bands are commonly employed in stents and catheters. These marker bands help guide healthcare professionals during procedures like angioplasty and stent placement. They ensure accurate positioning and alignment.

l Endoscopy: Ta marker bands are utilized in endoscopic instruments to help physicians navigate and locate specific areas within the gastrointestinal tract. So, they provide precise guidance during diagnostic and therapeutic procedures.

l Orthopedics: In orthopedic implants, such as hip or knee prostheses, these marker bands assist in the proper placement and alignment of the implant components. This ensures a secure fit and optimal joint function.

2. Industrial Applications:

Tantalum marker bands also have various industrial applications thanks to their unique properties. Here are some notable uses:

l Oil and Gas Industry: Ta marker bands are used in downhole tools and equipment for the oil and gas sector. They help track and measure the depth and position of the tools during drilling operations, allowing for precise wellbore placement and accurate data collection.

l Aerospace and Defense: They are applied in critical components of aircraft and aerospace equipment. They serve as reference points for alignment, quality control, and damage assessment. They ensure the safety and reliability of aerospace systems.

3. Other Uses:

You can also find such tantalum product useful in various other applications:

l Electronics and Quality Control: In the electronics and manufacturing industries, tantalum marker bands are used as reference points and indicators during the production and assembly of components. Their radiopacity and durability make them ideal for quality control and inspection processes.

l Research and Materials Testing: They are valuable in materials research and development. They can be embedded within test specimens to facilitate the study of material behaviors under various conditions and stresses.

l Scientific X-ray Imaging: In laboratory equipment and diagnostic devices, these marker bands are utilized to enhance X-ray visibility and imaging precision. They help identify and locate specific components or samples within imaging systems.

l Nuclear Medicine and Radiopharmaceuticals: They can also be integrated into radiopharmaceutical containers and delivery systems, aiding in the precise positioning and administration of radiopharmaceuticals for diagnostic and therapeutic purposes.

Related reading: SAM Launches Tantalum Marker Bands for the Medical Industry

In each of these applications, Ta marker bands contribute to accuracy, safety, and efficiency. Their radiopacity ensures that they are visible under imaging techniques like X-rays and makes them indispensable in medical procedures and diagnostics. Additionally, the corrosion resistance and biocompatibility of tantalum enhance its suitability for applications within the human body.

Conclusion

In a word, tantalum marker bands are unassuming yet critical components in medical, industrial, electronic, and various industries. They ensure precision and reliability in a wide range of applications. Their ability to withstand harsh environments, provide clear imaging, and offer biocompatibility makes them invaluable tools for both medical and industrial professionals seeking to achieve the highest standards of quality and performance.

Advanced Refractory Metal (ACM) provides radiopaque tantalum marker bands tailored to customer specifications in various industries, particularly the medical field. If you have any specific questions, please feel free to let me know.

Reference:

[1] Redhood, S. (2023, November 10). How do stents work? British Heart Foundation. Retrieved November 10, 2023, from https://www.bhf.org.uk/informationsupport/heart-matters-magazine/medical/how-do-stents-work