The Evolution of Electric Vehicle Batteries: From Lead-Acid to Lithium-Ion

Introduction

The development of electric vehicles (EVs) has undergone a remarkable transformation over the years, and at the heart of this evolution lies the battery technology that powers these vehicles. This article takes a journey through time to explore the evolution of electric vehicle batteries, from the early days of lead-acid batteries to the modern era dominated by lithium-ion technology.

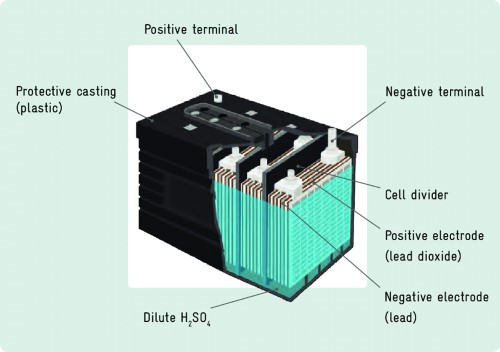

Lead-Acid Batteries: The Pioneers

In the late 19th century, lead-acid batteries emerged as the first widely used batteries for electric vehicles. These batteries utilized a chemical reaction between lead dioxide (positive plate), sponge lead (negative plate), and a sulfuric acid electrolyte to generate electrical energy. They played a crucial role in a variety of applications in the early days.

[1]

[1]

Figure 1. Typical Structure of Lead-Acid Batteries

However, these early EVs faced significant limitations due to the technology of their time. The limited energy density and range hindered their practicality for long journeys or inter-city travel. Besides, charging infrastructure during the early days was virtually non-existent, and recharging was a time-consuming process. This lack of convenience further limited the practicality of EVs.

Despite their challenges, lead-acid batteries remain in use today. They are commonly found in various applications, including automotive starting batteries, uninterruptible power supplies (UPS), and off-grid renewable energy systems.

Nickel-Metal Hydride Batteries: A Step Forward

In the early 20th century, Thomas Edison developed the nickel-iron battery. This rechargeable battery relies on an electrochemical reaction between a positive nickel oxide hydroxide electrode (NiOOH), a negative metal hydride electrode (MH), and an alkaline electrolyte. Although nickel-metal hydride batteries, or NiMH batteries, offered higher energy density and longer driving ranges, they didn't become a standard for EVs.

Lithium-Ion Batteries: The Game Changer

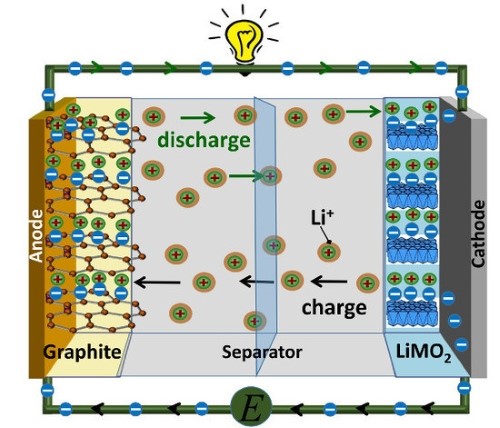

The 21st century witnessed a remarkable shift in EV battery technology with the widespread adoption of lithium-ion batteries. They come with higher energy density, longer range, and faster charging, making them the standard for modern electric vehicles. During charging, lithium ions (Li+) move from the cathode to the anode through the electrolyte, storing energy. In the discharge phase, these Li+ ions return to the cathode, generating an electric current.

[2]

[2]

Figure 2. Structure of Lithium-Ion Batteries

What sets Li-ion batteries apart are their exceptional features and diversity. They boast high energy density, sustainability, and a low self-discharge rate, retaining charge over time. Lithium-ion battery cathode comes in various materials such as lithium cobalt oxide (LiCoO2) for consumer electronics, lithium iron phosphate (LiFePO4) for electric vehicles, and lithium nickel cobalt manganese oxide (NCM) or lithium nickel cobalt aluminum oxide (NCA) for a balance between energy and power density.

This versatility empowers Li-ion batteries to fuel diverse applications, from consumer gadgets to electric vehicles, and spurs ongoing innovations, including solid-state batteries and cobalt reduction efforts, to further expand their capabilities and sustainability.

The Future of EV Batteries:

The evolution of EV batteries is far from over, and the future holds exciting prospects.

l Solid-State Batteries: The development of solid-state lithium-ion batteries represents a significant leap in battery technology. These batteries promise higher energy density, enhanced safety, and prolonged lifespan compared to traditional liquid electrolyte batteries.

l Reduced Cobalt: As environmental and ethical concerns surrounding cobalt mining persist, efforts are underway to reduce or eliminate cobalt in lithium-ion batteries. These endeavors aim to create more sustainable and responsible battery chemistries, minimizing the environmental and social impact associated with cobalt extraction.

l Fast Charging: Rapid advancements in fast-charging technology are revolutionizing EVs by making recharging as convenient as refueling traditional vehicles. Fast-charging infrastructure continues to expand, significantly reducing charging times and addressing one of the key barriers to EV adoption.

Conclusion

In summary, the evolution of electric vehicle batteries has been marked by significant advancements, with lithium-ion technology currently dominating the market. As technology continues to progress, the future of EV batteries promises even greater energy density, faster charging, and improved sustainability.

Stanford Advanced Materials (SAM) is a leading supplier of the Li-ion battery family. Send us an inquiry if you are interested.

Reference:

[1] Manhart, Andreas & Magalini, Federico & Hinchliffe, Daniel. (2018). End-of-Life Management of Batteries in the Off-Grid Solar Sector How to deal with hazardous battery waste from solar power projects in developing countries? Publication commissioned by: GIZ Sector Project Concepts for Sustainable Solid Waste Management and Circular Economy; developed in collaboration with Energising Development (EnDev).

[2] Madian, M.; Eychmüller, A.; Giebeler, L. Current Advances in TiO2-Based Nanostructure Electrodes for High Performance Lithium Ion Batteries. Batteries 2018, 4, 7. https://doi.org/10.3390/batteries4010007