Molybdenum Alloys in Medicine: Advancing Healthcare Technologies

The world of medicine is continuously evolving, and as technology progresses, so do the materials used in healthcare applications. One such material that has made significant strides in advancing healthcare technologies is molybdenum alloys. These alloys, primarily known for their remarkable strength, corrosion resistance, and high-temperature stability, have found a crucial place in various medical devices and equipment. In this article, we will delve into the innovative applications of molybdenum alloys in the field of medicine and how they are contributing to improved patient care and cutting-edge healthcare solutions.

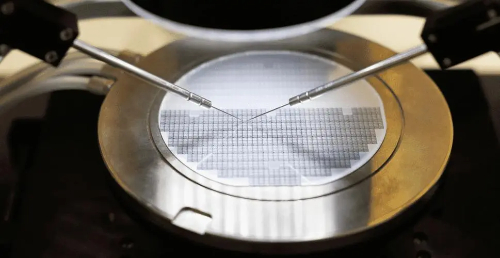

1. Imaging Equipment

One of the prominent areas where molybdenum alloys shine is in medical imaging equipment. Molybdenum-based components are commonly used in X-ray and computed tomography (CT) machines. The high melting point and excellent thermal conductivity of molybdenum alloys make them ideal for X-ray tube anodes, which need to withstand intense heat during operation. The result is more accurate and faster imaging processes, ultimately benefiting both patients and healthcare professionals.

2. Radiation Therapy

Molybdenum alloys are employed in radiation therapy, a critical aspect of cancer treatment. Devices such as linear accelerators use molybdenum components for their ability to withstand high-energy radiation beams. These alloys help shape and direct the radiation precisely to target cancer cells while minimizing damage to surrounding healthy tissue. This precision is vital in enhancing the effectiveness of cancer treatments and minimizing side effects for patients.

3. Orthopedic Implants

Orthopedic surgeries often require the use of strong, biocompatible materials for implants. Molybdenum-based alloys, particularly those containing titanium and zirconium, have gained popularity in the production of orthopedic implants, including hip and knee replacements. These alloys are not only durable but also resist corrosion within the body, providing long-lasting support and relief to patients suffering from joint problems.

4. Dental Instruments

Dentistry has also benefited from the use of molybdenum alloys. Dental instruments, such as forceps, scalpels, and mirror handles, often utilize molybdenum for its high strength, corrosion resistance, and ability to maintain sharp edges. This ensures that dental professionals can provide efficient and precise dental care, enhancing patient comfort and outcomes.

5. Neurosurgical Tools

In neurosurgery, where precision is paramount, molybdenum-based instruments have become invaluable. Neurosurgeons rely on these instruments for their exceptional strength and durability. Molybdenum's ability to maintain sharp edges even after repeated use is critical when working on delicate brain and spinal procedures.

6. Cardiac Devices

Molybdenum alloys also play a role in cardiac healthcare. Pacemakers and implantable cardioverter-defibrillators (ICDs) often contain molybdenum components. The biocompatibility and resistance to corrosion make these alloys ideal for ensuring the longevity and reliability of these life-saving devices.

7. Research and Development

Beyond medical devices, molybdenum alloys are essential in medical research and development. They are used in laboratories for their compatibility with harsh chemical environments, ensuring the accuracy of experiments and analyses.

As technology continues to advance, molybdenum alloys are likely to play an even more significant role in the healthcare industry. Their unique combination of properties, including biocompatibility, strength, and resistance to corrosion, positions them as valuable materials for developing cutting-edge medical devices and technologies.

In conclusion, molybdenum alloys are quietly but steadily advancing healthcare technologies in various critical areas. Whether it's improving the quality of diagnostic images, enhancing the durability of surgical instruments, or enabling innovative research, molybdenum's properties are helping to shape the future of healthcare. As medical science continues to evolve, we can expect to see even more ingenious applications of these remarkable alloys in the pursuit of better patient care and medical advancements.