Gas-Atomized Spherical Powders: Addressing the Technological and Practical Challenges

1. Introduction

Spherical metal powder has become an important raw material of Additive Manufacturing (AM) due to its excellent properties such as homogeneity and fluidity, which improve the quality and forming efficiency of printed parts. At the same time, it can be recycled and reused, which reduces the cost and impact on the environment.

2 Spherical Powders

2.1 What is Spherical Powder?

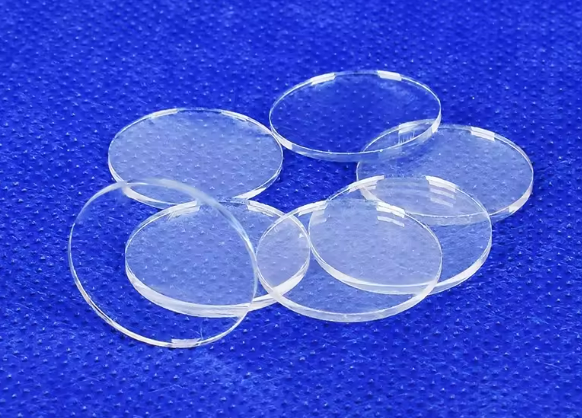

Metal 3D printing relies heavily on spherical metal powder, which serves as its foundational material and constitutes a critical component of the industry's supply chain. The advancement of 3D printing technology is intricately tied to the development of these metal powders. Currently, the predominant materials utilized for metal 3D printing encompass iron, titanium, cobalt, copper, nickel, and various alloys thereof.

2.2 What are the Characteristics of Spherical Powders?

The unique structure of spherical powder makes it have some unique properties that cannot be compared with ordinary powder, and it can be used in applications with higher requirements for the material structure.

1. High uniformity: Due to its spherical structure, the particle size distribution of spherical powder is relatively narrow. The structure can ensure the high uniformity of powder particles in the molding process, greatly improving the precision and quality of the prepared materials, and making the best use of the physical and chemical properties of the materials.

2. Compressibility: The structure of the spherical powder is compact, with very good compressibility and plasticity, making the spherical powder prepare a variety of complex structures of the material, and reduce the scrap rate in the production process.

3. Fluidity: Spherical powder has excellent fluidity, because of its particle shape rules, spherical particle size distribution is more uniform. There will be no particles staggered, piling up, and so on, so the production process is more efficient, reducing production time and cost.

2.3 What are the Applications of Spherical Powders?

In addition to the aforementioned 3D printing, spherical powders can also be used in powder metallurgy, material additives, and catalyst carriers.

1. Metal 3D Printing: Spherical metal powder is one of the key raw materials in metal 3D printing technology. In processes such as powder bed sintering (e.g., selective laser sintering) and direct energy deposition (e.g., laser melting), spherical powders can provide good flowability and stackability, as well as high density and forming quality.

2. Powder Metallurgy: Spherical powders are widely used in powder metallurgy processes for the preparation of metal parts and materials. The homogeneity and flowability of spherical powders help to ensure the denseness and mechanical properties of the formed parts.

3. Coating and Spraying: Spherical powders are commonly used in the preparation of coated materials, such as thermal spraying, cold spraying, and plasma spraying. The shape and particle size distribution of spherical powders ensures uniform spray coatings and improves coating adhesion and wear resistance.

4. Preparation of Composites: Spherical powders can be combined with resins, ceramics, polymers, and other materials to prepare composites for use in the manufacture of structural and functional parts in automotive, aerospace, construction, and other fields.

5. Catalyst: In the field of the chemical industry, the spherical powder is often used as the carrier of catalyst, applied to chemical reactions, environmental protection, and energy conversion.

3 Preparation of Spherical Powder

Aerosolization processing is the process of atomizing solid powders into tiny particles utilizing gas injection or mechanical vibration, etc. and forming a suspended liquid mist in the air. The gas atomization uses high-pressure gas flow (usually inert gas) to atomize the powder.

Because the specific heat capacity of gas is smaller than that of water. It will take more time for droplets to cool down and consolidate. As a result, the powder produced by gas atomization will be more spherical than water atomization (WA), by which the powder produced is usually irregular and not used in 3D printing.

Atomization starts by melting the raw alloy/metal (any shape will do) in a furnace. Then, it is held for some time to ensure an even distribution of the melting liquid. Afterward, the liquid is transferred to a crucible with a refractory nozzle with a controlled flow rate. The nozzle is opened and the liquid is allowed to enter the atomization chamber. It falls freely and is then cooled, atomized, and solidified by a high-velocity air stream. Finally, the powder can be collected at the bottom of the chamber. Another step required later is to dry the powder.

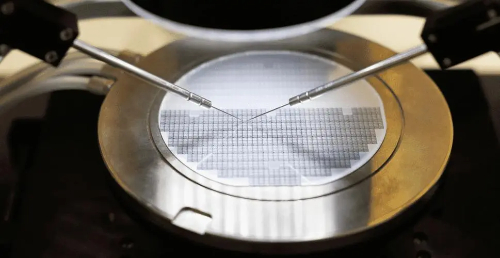

3.1 Inert Gas Atomization

The principle is that the molten metal liquid stream is impacted and broken by the high-speed airflow to form metal powder by fast cooling. There are two main types of nozzles for gas atomization: free-fall nozzles and close-coupled nozzles. The free-fall nozzle design is relatively simple, the nozzle is not easy to clog, and the control process is relatively simple, but the atomization efficiency is low. The close-coupled nozzle design is compact, shortens the flight distance of the gas, reduces the gas atomization process with less energy loss, the fluid medium can be fully crushed metal liquid flow, and nozzle atomization efficiency is high.

3.1.1 Plasma Inert Gas Atomization (PIGA)

The raw material is formed into pre-alloyed rods and melted using plasma arc heat in a water-cooled copper crucible, the bottom of which is connected to an induction heating nozzle, a ceramic-free nozzle system that introduces a liquid stream of molten metal into the gas atomization nozzle for atomization. the advantage of the PIGA technology is that the plasma gun does not come into contact with the raw material rods during the melting process, thus preserving the purity of the process.

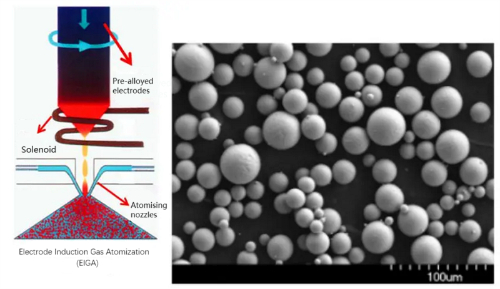

3.1.2 Electrode Induction Gas Atomization (EIGA)

Electrode induction melting gas atomization (EIGA) represents an innovative approach derived from traditional gas atomization techniques. Unlike conventional methods utilizing crucibles to contain molten metal, EIGA employs rotating metal rods as its primary feedstock, melted via induction heating, with the molten material directly entering the atomization chamber. This design circumvents contact with crucibles during the melting process, thereby preventing contamination and ensuring the purity of the atomized powder.

EIGA technology offers several advantages over traditional crucible aerosolization methods, including minimal raw material pollution, rapid heating rates, streamlined processes, and easy-to-maintain equipment.

However, EIGA technology also presents challenges:

1. The induction coil imposes limitations on the diameter of the raw material bar for the induction electrode. Larger diameter electrodes necessitate higher induction heating power supplies and coils, resulting in increased costs that hinder the development of large-diameter rod atomization.

2. Maintaining stable cooperation between the vertical feeding speed and electrode rotational speed to ensure the electrode remains securely within the coil is a complex issue that requires resolution.

3. Achieving a stable and uninterrupted flow of metal droplets during electrode induction heating and melting into the aerosol nozzle poses difficulties. The actual atomization process may result in droplet-like formations or incomplete melting of the electrode leading to conduit blockages. Thus, maintaining liquid flow stability represents a significant challenge in current EIGA technology.

3.1.3 Plasma Atomization (PA)

Plasma atomization (PA) utilizes plasma as the primary heat source to melt feedstock material, typically in powder or wire form. When the feedstock is exposed to the plasma torch, it undergoes simultaneous melting and atomization due to inert gas jets. Subsequent steps in the process mirror those of gas atomization.

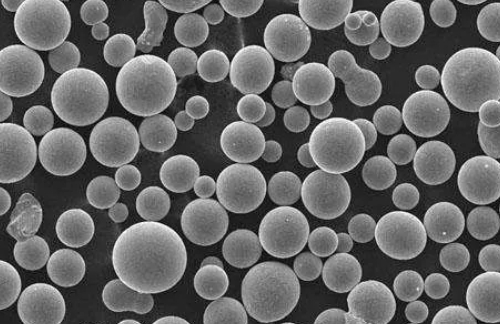

Compared to conventional methods, plasma atomization yields powder with superior characteristics. The particle size distribution of alloy powder produced via plasma atomization is notably narrower, ranging from 10 to 150 μm, with approximately 40% of the powder falling below 50 μm, resulting in a significant proportion of fine powder. Additionally, PA-derived powders exhibit high sphericity and minimal impurity content, further enhancing their quality and suitability for various applications. [1]

3.2 Centrifugal Atomization

3.2.1 Plasma Rotating Electrode Method

The anode metal rod is placed on a high-speed rotating shaft and melted under the action of the plasma arc. The molten metal droplets are dispersed into small droplets in the tangential direction under the action of the centrifugal force and eventually solidify and spherical into powder, and the whole process is carried out in a vacuum or under the protection of an inert gas atmosphere.[2]

3.2.2 Rotating Disc Centrifugal Atomization

Centrifugal atomization is a method of atomization in which the molten metal liquid is sheared along the tangential direction in a rotating disc at high speed and condensed into powder by spheroidization. The average particle size of the powder prepared by centrifugal atomization is more than 100 μm, and the particle size of the powder is related to the centrifugal rate of the rotating disc. [3]

3.3 Plasma Torch Atomization Technology

Plasma atomization technology is a dual-flow atomization technology, the heating source consists of 3 plasma torches, the raw material wire is heated and melted by the plasma arc, and then fully specialized and solidified into powder under the action of high-temperature atomizing gas. The plasma atomization technology enables the melting and atomization processes to take place at the same time, and the average particle size of the powder is 40 μm, which is a fine powder with a high degree of sphericity.

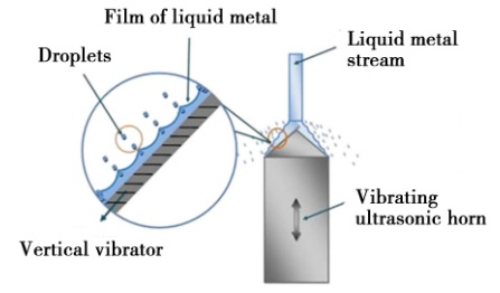

3.4 Ultrasonic Atomization Method

The powder prepared by ultrasonic aerosolization technology is fine, fast cooling speed, a smooth surface, and almost no satellite powder particles. Ultrasonic aerosolization powder-making technology is the use of ultrasonic vibration energy and airflow impact kinetic energy to make the liquid stream broken, powder-making efficiency is significantly improved, but still needs to consume a lot of inert gas.

3.5 Plasma Spheroidization

Radio Frequency (RF) plasma in the powder spheronization process, its high temperature provides the energy to make the powder in the plasma across the rapid absorption of heat, melt, and under the action of surface tension condensed into a spherical shape, in a very short period suddenly cold solidification, thus forming a spherical powder.

Table 1 Comparison of different preparation methods

|

Methods |

Advantages |

Drawbacks |

|

Gas Atomization |

(1) High powder production efficiency (2) Good sphericity (3) Mature production process |

(1) High equipment cost (2) High requirements for raw materials (3) A smaller range of powder sizes can be produced |

|

Ultrasonic Atomization |

(1) Suitable for special metal materials (2) No need for high temperatures during production (3) Uniform powder size distribution without large particles |

(1) Lower powder production efficiency (2) High requirements for raw material particle size (3) Requires specialized ultrasonic equipment |

|

Centrifugal Atomization |

(1) Ability to produce high-purity powders (2) Applicable to various metal materials (3) Wide control of particle size distribution |

(1) Lower powder production efficiency (2) High investment and operating costs (3) Some metals are susceptible to oxidation |

|

Plasma Spheroidization |

(1) Ability to produce high-purity, micron-sized metal powders (2) Applicable to various metal materials (3) Able to operate at low temperatures |

(1) High equipment cost (2) High technical operation requirements (3) Requires control of the gas environment and plasma |

4 Challenges in Processing

4.1 Hollow Powder

The hollow powder is a common class of defects in aerosolized powders, holes in the powder generally exist in two forms: one is the atomized gas is wrapped in the powder inside the formation of closed pores, the size of which is generally 10% to 90% of the powder, generally in the coarser particle size (>70 μm) of the powder is most common; the other is the formation of pores between the dendrites of the solidification of the contraction of the pores, the size of which is generally less than 5% of the size of the powder, and is distributed both inside and on the surface of the powder. The other is the pores formed by solidification and shrinkage between dendrites, the size of which is generally less than 5% of the powder size, and are distributed in the powder and on the surface. Generally speaking, with the increase of powder particle size, the number, size and gas content of the pores in the powder will increase accordingly.

The formation of hollow powders is related to the droplet fragmentation mechanism during the atomization process. During the aerosolization process, there are many different types of droplet fragmentation mechanisms occurring simultaneously, depending on the energy of the interaction between the atomizing gas and the molten metal. When one of the most energetic mechanisms, bag crushing, occurs, large droplets form bag-like sheets under the action of the gas flow, spreading in a direction perpendicular to the gas flow. When the viscosity of the liquid is small, the outside of the liquid film breaks up to form tiny droplets; however, the droplets cool very quickly during aerosolization, and the viscosity rises sharply as the droplet temperature drops rapidly. When the droplet viscosity is high enough, the crushing of the bagging film is suppressed, and the ports on both sides of the liquid film combine to form a hollow droplet wrapped with atomized gas. Therefore, the energy of the crushing process must be reduced in order to inhibit the generation of hollow powder to avoid bag crushing.

4.2 Satellite Powder

Satellite powder refers to small particles that adhere to the surface of larger particles, forming a satellite-like structure within the powder. This phenomenon diminishes powder sphericity, fluidity, and bulk density, presenting a common flaw in aerosolized powders. Moreover, the formation of satellite powder often leads to the aggregation of larger particles due to adsorption and surface tension forces. Consequently, these adherent satellite particles pose challenges for effective separation during subsequent processing stages.

To address this issue, current research focuses on two primary methods for reducing satellite powder formation. Firstly, by meticulously controlling the atomization process and the properties of the molten material, efforts are made to narrow the particle size distribution of the atomized powder. This reduction in particle size disparity aims to minimize variations in powder motion states, thereby decreasing collision frequencies between powder particles and liquid droplets. Secondly, the introduction of auxiliary airflow into the atomization chamber or optimization of chamber structure serves to inhibit internal airflow turbulence, subsequently lowering the likelihood of collisions between powder particles and liquid droplets.

4.3 Powder Size Distribution Control

After undergoing pre-screening, the larger particles in the powder are removed. Narrowing the distribution width of powder sizes can enhance powder yield, effectively reducing the production costs associated with powder manufacturing.

Optimizing nozzle structure design is paramount in controlling powder size distribution. Schwenck et al. [4] devised a shrink-expand ring-seam nozzle featuring a throat diameter of 0.8 mm, contrasting it with conventional shrink-ring-seam nozzles of 0.8 mm and 0.4 mm diameters. Results indicated that powders generated by the shrink-expand ring-seam nozzle exhibited smaller median particle sizes compared to those from conventional nozzles.

Furthermore, the geometric standard deviation of powder size decreased from 2.14 to 1.87, indicating a narrower powder size distribution and heightened powder yield. Additionally, the study explored the impact of hot gas atomization, revealing that heating the gas to 320°C further reduced powder particle size and distribution, thus improving powder yield.

5 Prospects for the Development of Spherical Powder Preparation Technology

Additive manufacturing (AM) is an advanced metal material rapid prototyping technology, also known as 3D printing technology, that works from digital model files and uses metal powder materials to build parts by printing them layer by layer. In addition to plastics, which are more common in everyday life, raw materials used in 3D printing include metals and ceramics for high-strength and corrosion-resistant parts, as well as biomaterials used in medicine and biology.

Additive manufacturing products have fine grain size, uniform composition, excellent performance, part performance can be controlled point by point, no wall thickness position effect, reducing the macro-metallurgical defects and segregation of traditional casting and forging, and at the same time, get rid of the traditional metallurgical process on the alloy composition of the limitations.

Due to the increasing sophistication of spherical powder processing technology, the processes used in additive manufacturing to make metal parts have a higher degree of precision, purity, and suitability for the application. It can be said that the development of spherical powder manufacturing technology is also closely related to the development of the field of additive manufacturing.

6 Conclusion

As an important raw material for additive manufacturing, the quality of spherical powder directly determines the performance quality of the finished parts, therefore, the control of the preparation process and the upgrading of technology for spherical powder is crucial. At present, the mainstream method of preparing spherical powder is based on aerosolization, in which the solid powder is atomized into tiny particles by gas injection or mechanical vibration, and a suspension mist is formed in the air, and the powder particles are close to spherical under the action of surface tension. Problems occurring in the process are mainly concentrated in the hollow powder problem and satellite powder problem, while the control of the powder particle size is also a key step to affect the quality of the powder.

Related reading:

SPHERICAL POWDERS UNDER THE MICROSCOPE HOW PARTICLE SHAPE INFLUENCES FUNCTIONALITY

Satellite Phenomena in Metal Powder: A Deep Dive into Additive Manufacturing Challenges

Reference:

[1] KROEGER J, MARION F. Raymer AP&C: Leading the way with plasma atomized Ti spherical powders for MIM[J]. Powder Injection Moulding International, 2011, 5(4): 55.

[2] Savage S J. Production of rapidly solidified metals and alloys [J]. Journal of Metals, 1984, 36(4): 20.

[3] Leo V M Antony, Ramana G Reddy. Processes for the production of high purity metal powders [J]. High Purity Metals, 2003, 3: 14.

[4] SCHWENCK D, ELLENDT N, FISCHER-Bühner J, et al. A novel convergent–divergent annular nozzle design for close-coupled atomization [J]. Powder Metallurgy, 2017, 60(3): 198-207.