Precious Metal Catalysts: A Closer Look at the Influence of Particle Size

In the world of chemical reactions and industrial processes, catalysts play a pivotal role in facilitating reactions, reducing energy consumption, and increasing the efficiency and selectivity of chemical transformations. Among the various types of catalysts used, precious metal catalysts stand out for their exceptional activity and stability. These catalysts, made from metals such as platinum, palladium, gold, and silver, are crucial in a wide range of applications, from automotive exhaust systems to pharmaceutical synthesis. This article delves into the critical aspect of particle size in precious metal catalysts and its profound influence on their performance.

What is the effect of particle size on the catalyst?

The effect of particle size on catalyst performance is a fundamental aspect of catalysis that has significant implications for chemical reactions in various industrial processes. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process.

Precious metal catalysts, such as those made from platinum, palladium, rhodium, and gold, are particularly valued for their high catalytic activity and selectivity. The particle size of these catalysts plays a critical role in determining their efficiency, selectivity, and stability.

Changing the particle size of a catalyst can significantly affect the rate of reaction. This influence is rooted in several key aspects of catalysis and surface science. Here's a brief overview of how and why the particle size impacts the reaction rate:

1. Surface Area to Volume Ratio

Increased Surface Area: Smaller particles have a higher surface area to volume ratio, providing more active sites for the chemical reaction to occur. This can significantly enhance the catalytic activity because more reactant molecules can interact with the catalyst surface.

Maximized Reactivity: By maximizing the surface area available for reactions, smaller catalyst particles can facilitate faster reaction rates and higher efficiencies.

2. Catalytic Activity

Enhanced Activity with Decreased Size: Reducing particle size often leads to an increase in catalytic activity. This is because a larger proportion of the catalytic material is exposed to the reactants, allowing for more effective interactions.

Optimal Particle Size: There is often an optimal particle size that provides the best balance between high catalytic activity and efficient use of the material. Too small particles may agglomerate, reducing their effective surface area.

3. Selectivity

Influence on Reaction Pathways: The size of catalyst particles can influence the selectivity of the reaction, which is the ability of the catalyst to favor the formation of certain products over others. Smaller particles may offer different active sites compared to larger ones, leading to variations in the reaction pathways that are favored.

Tuning Product Distribution: By controlling particle size, chemists can tune the catalyst to optimize the yield of desired products, which is particularly important in pharmaceuticals, fine chemicals, and petrochemicals production.

4. Stability and Resistance to Deactivation

Sintering and Agglomeration: Smaller particles are more prone to sintering, a process where particles coalesce and grow larger under high temperatures or reaction conditions, potentially reducing the catalyst's active surface area over time.

Deactivation Mechanisms: The stability of a catalyst and its resistance to deactivation mechanisms, such as poisoning by impurities or coking (the deposition of carbonaceous materials), can be affected by particle size. Smaller particles may have higher reactivity but also a greater susceptibility to deactivation.

5. Diffusion Limitations

Mass Transport Effects: In reactions where diffusion limitations are significant, the size of catalyst particles can influence the rate at which reactants reach the active sites and products are removed. Larger particles may suffer from internal diffusion limitations, slowing down the overall reaction rate.

6. Economic Considerations

Material Efficiency: Smaller particles utilize the precious metal more efficiently, as a larger fraction of the metal is available for the reaction. However, the synthesis of nanoparticles with controlled size and shape can be more complex and costly.

Does changing the particle size of a catalyst affect the rate of reaction?

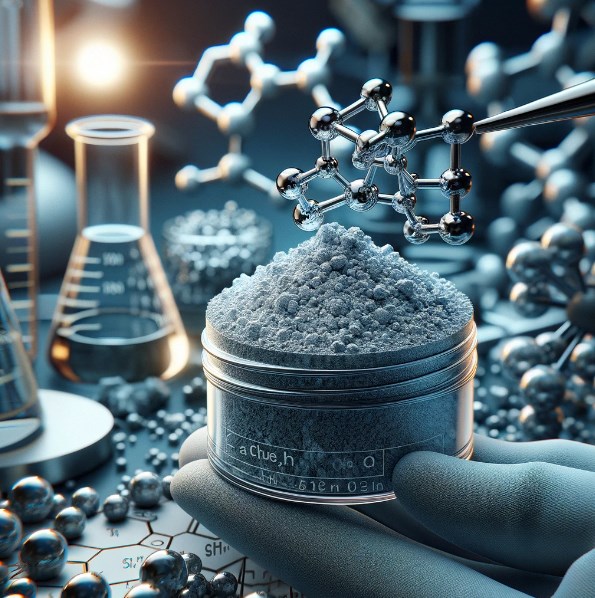

Advancements in nanotechnology and materials science have led to the development of various methods for controlling the particle size of precious metal catalysts. These include:

Chemical Reduction: By adjusting the concentration of the metal precursor and the reducing agent, along with the reaction conditions such as temperature and pH, it is possible to synthesize nanoparticles of specific sizes.

Sol-Gel Methods: This involves the transition of a system from a liquid "sol" (mostly colloidal) into a solid "gel" phase. By controlling the sol-gel process, particles of precise sizes can be obtained.

Template-Assisted Synthesis: Using a template that has pores or cavities of a specific size can help in forming metal particles with sizes that match those of the template features.

Why are precious metals used in catalytic converters?

Precious metals are used in catalytic converters due to their exceptional catalytic properties, which are crucial for the efficient conversion of exhaust gases from internal combustion engines into less harmful substances. Catalytic converters are designed to reduce the emission of pollutants such as carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons (HC). The precious metals commonly used in catalytic converters include platinum (Pt), palladium (Pd), and rhodium (Rh), each offering unique advantages in the catalysis process. Here are the main reasons why these precious metals are chosen:

High Catalytic Activity

Efficiency: Precious metals are highly effective at facilitating the chemical reactions needed to convert toxic gases into less harmful ones. They provide active sites that can adsorb reactant molecules and lower the activation energy required for the reactions to proceed, enhancing the overall efficiency of the conversion process.

Thermal Stability

Durability at High Temperatures: Catalytic converters operate under high-temperature conditions. Precious metals maintain their catalytic activity and structural integrity at these elevated temperatures, ensuring the converter's effectiveness over a wide range of operating conditions.

Resistance to Poisoning

Chemical Stability: Precious metals exhibit resistance to poisoning by contaminants that may be present in the exhaust gases, such as sulfur and lead. Catalyst poisoning can deactivate the catalyst by blocking its active sites. The resilience of precious metals helps prolong the life of the catalytic converter and maintain its performance.

Oxidation and Reduction Capabilities

Versatility in Reactions: The precious metals used in catalytic converters have the ability to catalyze both oxidation and reduction reactions:

Platinum and Palladium: These metals are excellent at oxidizing carbon monoxide (CO) to carbon dioxide (CO2) and hydrocarbons (HC) to CO2 and water (H2O), thereby reducing harmful emissions.

Rhodium: Rhodium is particularly effective at reducing nitrogen oxides (NOx) to nitrogen (N2) and oxygen (O2), addressing one of the most challenging aspects of exhaust treatment.

Complementary Action

Synergistic Effects: Using a combination of these precious metals takes advantage of their complementary properties to cover a broad spectrum of reactions efficiently. For example, a catalytic converter might use platinum for its strong oxidation capabilities and rhodium for its ability to reduce NOx, optimizing the conversion of a wide range of pollutants.

Applications and Future Directions

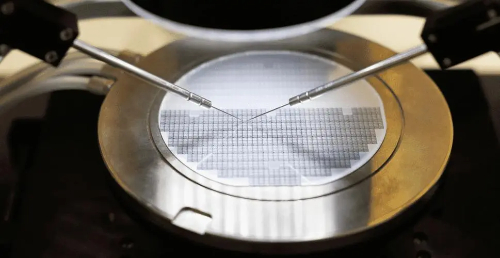

The control of particle size in precious metal catalysts opens up new possibilities for their application across various industries. In automotive catalytic converters, optimizing the size of platinum and palladium particles has significantly improved the removal efficiency of harmful emissions. In the pharmaceutical industry, gold and palladium catalysts with tailored particle sizes are being explored for their ability to catalyze key reactions under mild conditions, enhancing the sustainability of drug synthesis.

Looking ahead, the ongoing research aims to further understand the relationship between particle size and catalytic behavior at the atomic level. This knowledge will guide the development of next-generation catalysts with even higher performance, durability, and selectivity. Moreover, the exploration of bimetallic nanoparticles and the effect of particle size in these systems promise to unlock new catalytic properties and applications.

Conclusion

The influence of particle size on the performance of precious metal catalysts is a fascinating aspect of catalysis that blends fundamental science with practical applications. As our ability to precisely control particle size continues to advance, so too will our capacity to design more efficient, selective, and sustainable catalytic processes, highlighting the ever-growing importance of precious metal catalysts in modern industry and technology.